Difference between revisions of "Flash Coolers"

| Line 8: | Line 8: | ||

*-------------------------------------------------></noinclude> | *-------------------------------------------------></noinclude> | ||

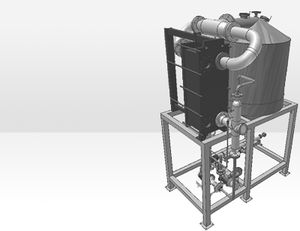

[[File:Flash cooler.jpg|thumb|right|Flash Coolers]] | [[File:Flash cooler.jpg|thumb|right|Flash Coolers]] | ||

[[File:Flash-recovery-using-a-flash-cooler.gif|thumb|right|Flash recovery using flash coolers]] | [[File:Flash-recovery-using-a-flash-cooler.gif|thumb|right|Flash recovery using flash coolers]] | ||

The | The '''Flash Cooler''' system is simple and consists only of a vacuum chamber (the vacuum is created by steam jet vacuum units) into which the concentrate is sprayed. Depending upon the vacuum the concentrate will flash and due to the evaporation, cooling will take place simultaneously resulting in a slight increase of the solids content. | ||

Often the required concentrate temperature is lower than the one obtained in the last effect. Flash coolers are recommended instead of naturally passing the concentrate over a cooling surface, such as a plate | Often the required concentrate temperature is lower than the one obtained in the last effect. Flash coolers are recommended instead of naturally passing the concentrate over a cooling surface, such as a plate [[Heat Exchangers]], due to the high viscosity at this stage. | ||

The flash cooler is mainly used for whey, where it is especially advantageous, as the cooling takes place instantaneously, thereby avoiding problems with crystallization of the lactose, which would create blockages between the plates. | The flash cooler is mainly used for whey, where it is especially advantageous, as the cooling takes place instantaneously, thereby avoiding problems with crystallization of the lactose, which would create blockages between the plates. | ||

Latest revision as of 01:08, 4 August 2012

The Flash Cooler system is simple and consists only of a vacuum chamber (the vacuum is created by steam jet vacuum units) into which the concentrate is sprayed. Depending upon the vacuum the concentrate will flash and due to the evaporation, cooling will take place simultaneously resulting in a slight increase of the solids content.

Often the required concentrate temperature is lower than the one obtained in the last effect. Flash coolers are recommended instead of naturally passing the concentrate over a cooling surface, such as a plate Heat Exchangers, due to the high viscosity at this stage.

The flash cooler is mainly used for whey, where it is especially advantageous, as the cooling takes place instantaneously, thereby avoiding problems with crystallization of the lactose, which would create blockages between the plates.