Difference between revisions of "Fabric Filters"

| Line 22: | Line 22: | ||

== | ==Parts== | ||

* Clean plenum | * Clean plenum | ||

* Dusty plenum | * Dusty plenum | ||

| Line 30: | Line 30: | ||

* Compressed air header | * Compressed air header | ||

* Blow pipe | * Blow pipe | ||

* [[Filter Housings|Housing]] and [[Hoppers|hopper]] | |||

Revision as of 23:11, 13 January 2013

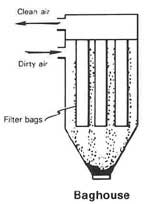

Commonly known as baghouses, fabric filters use filtration to separate dust particulates from dusty gases. They are one of the most efficient and cost effective types of dust collectors available and can achieve a collection efficiency of more than 99% for very fine particulates.

Dust-laden gases enter the baghouse and pass through fabric bags that act as filters. The bags can be of woven or felted cotton, synthetic, or glass-fiber material in either a tube or envelope shape.

Types of Bag Cleaning

Baghouses are characterized by their cleaning method.

Shaking

A rod connects to the bag is powered by a motor that provides motion to remove the caked on particles. The speed and motion of the shaking depends on the design of the bag and composition of the particulate matter. Though, generally shaking is horizontal. The top of the bag is closed and the bottom is open. When shaken the dust collected on the inside of the bag is set free. During the cleaning process, no dirty gas flows through a bag while the bag is being cleaned. This redirection of air flow illustrates why baghouses must be compartmentalized.

Reverse Air

Air flow gives the bag structure. Dirty air flows through the bag from the inside, allowing dust to collect on the interior surface. During cleaning, gas flow is restricted from a specific compartment. Without the flowing air, the bags relax. The cylindrical bag contains rings that prevent it from completely collapsing under the pressure of the air. A fan blows clean air in the reverse direction. The relaxation and reverse air flow cause the dust cake to crumble and release into the hopper. Upon the completion of the cleaning process, dirty air flow continues and the bag regains its shape.

Pulse Jet

This type of baghouse cleaning (also known as pressure-jet cleaning) is the most common. A high pressure blast of air is used to remove dust from the bag. The blast enters the top of the bag tube, temporarily ceasing the flow of dirty air. The shock of air causes a wave of expansion to travel down the fabric. The flexing of the bag shatters and discharges the dust cake. The air burst is about 0.1 second and it takes about 0.5 seconds for the shock wave to travel down the length of the bag. Due to its rapid release, the blast of air does not interfere with contaminated gas flow. Therefore, pulse-jet baghouses can operate continuously and are not usually compartmentalized. The blast of compressed air must be powerful enough to ensure that the shock wave will travel the entire length of the bag and fracture the dust cake.

Sonic

The least common type of cleaning method is sonic. Shaking is achieved by sonic vibration. A sound generator produces a low frequency sound that causes the bags to vibrate. Sonic cleaning is commonly combined with another method of cleaning to ensure thorough cleaning.

Parts

- Clean plenum

- Dusty plenum

- Bag, cage, venturi assembly

- Tubeplate

- Screw conveyor

- Compressed air header

- Blow pipe

- Housing and hopper

Advantages

A major advantage of a fabric filter is its ability to cope with virtually any fly ash, with practically no change in the outlet emission.

Video