3D Designing

3D Designing technology is the must-have design tool and it’s not just for the biggest aerospace and automotive manufacturers who require their suppliers to provide 3D models. Research shows 3D design and engineering is increasingly prevalent among mainstream manufacturers as well. In fact, estimates put spending at $7 billion worldwide on 2D and 3D design technology and data management solutions. The time is right for manufacturers of all sizes to consider the value of investment in 3D. Changing market conditions and technological advances indicate 3D design technology can reinvigorate productivity, sharpen competitive edge, earn even greater return on investment in product design, and benefit many other aspects of manufacturing.

Impact of 3D

Three-dimensional design technology helps improve the design process that in turn benefits business. Manufacturers find that migrating from 2D to 3D tools makes design work more efficient and accurate, producing better overall design quality and fewer errors. Exploration of new design ideas becomes easier because engineers don’t have to spend time making new 2D drawings in order to look at design alternatives. The use of 3D tools also can help communicate concepts to a diverse audience, without sacrificing tried-and-true modes of communication with suppliers and partners. As a result, design teams are more productive; companies can get better products to manufacturing – and even get them to market faster; and firms can improve styling and innovation cost-effectively for competitive advantage, as well as business growth.

Efficient Design: Faster, Easier Drafting

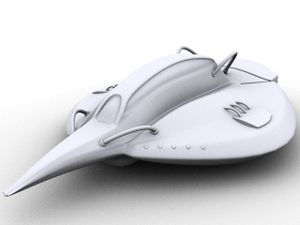

Three-dimensional modeling software handles a number of tough drawing exercises to help users understand their designs and make better decisions earlier in the product development process to save time and reduce the likelihood of error. When it comes to representation, 3D design software can create everything that a 2D application can. But new 3D modeling tools make it possible to create and modify some of the most challenging objects to design. These 3D applications produce accurate representations of highly complex parts, such as casings that have curved surfaces; very large assemblies containing thousands of parts; and appropriately routed tubes and wiring.

New 3D tools also automatically generate front, side, iso, detail, section, and auxiliary views based on automatic retrieval of model dimensions. Layering capabilities make it easier to map groups of elements between 3D and 2D applications, for easy importing and exporting of data. Quite simply, 3D technology is the fastest way to create a drawing. Powerful computational capabilities and content libraries built into 3D software streamline mechanical design tasks such as shaft, cam, and gear generation as well. In addition, 3D tools perform interference detection and calculate weight and mass. These automated functions make it faster and easier to change designs, too. All of these capabilities mean that 3D models can be created and updated easily and quickly, and concepts can be visualized more clearly than is possible from a collection of 2D elements.

Accuracy Matters:Design Updates and Associativity

Getting a design finished and into production is more than a question of speed; it’s a matter of accuracy. When complex designs incorporate thousands of parts and assemblies, accuracy can have a huge impact on the time and cost of bringing a new product to market. Three-dimensional models offer huge advances in error checking. In part, this is possible because 3D design applications capture product parts association to one another and show users how those parts interact. Design changes are made more efficiently using 3D design technology, too, because the software updates all associated drawings and assembly components automatically – where 2D designs might require days or weeks of modification. The smart associative capabilities of 3D design technology also support design intent. By maintaining the connection among product elements, 3D tools help to ensure that the design remains intact as it was intended to fill a business or functional need, or both. This design intent is important when proven designs serve as the foundation for new products, and when their creators may have moved on to another project or company.