Difference between revisions of "Absolute Filters"

| Line 12: | Line 12: | ||

[[File:Absolute_Filters_process_outline.jpg|thumb|right|Working outline of absolute filters]] | [[File:Absolute_Filters_process_outline.jpg|thumb|right|Working outline of absolute filters]] | ||

An absolute filter is a [[Filters|filter]] capable of cutting off 100% by weight of solid particles greater than a stated micron size. Absolute Rating is a term used to describe or define the degree of [[Filtrations|filtration]] of absolute filter. Various methods are used to determine absolute ratings which are not necessarily interchangeable. Generally absolute means 100% removal of solids above a specified micron size by use of absolute filter. Below please find suppliers of absolute filter. | An '''absolute filter''' is a [[Filters|filter]] capable of cutting off 100% by weight of solid particles greater than a stated micron size. Absolute Rating is a term used to describe or define the degree of [[Filtrations|filtration]] of absolute filter. Various methods are used to determine absolute ratings which are not necessarily interchangeable. Generally absolute means 100% removal of solids above a specified micron size by use of absolute filter. Below please find suppliers of absolute filter. | ||

Revision as of 22:19, 16 September 2012

An absolute filter is a filter capable of cutting off 100% by weight of solid particles greater than a stated micron size. Absolute Rating is a term used to describe or define the degree of filtration of absolute filter. Various methods are used to determine absolute ratings which are not necessarily interchangeable. Generally absolute means 100% removal of solids above a specified micron size by use of absolute filter. Below please find suppliers of absolute filter.

Reasons of areas with an important need for eliminating submicron particles could be bomb shelters gas masks, optic and precision mechanical production, sensitive electronic components computer, nuclear inslallation clean room systems pharmaceutical industry laminar flow workirg bench, hospilal slerile areas, space application food processing zones, biological centre and many more. Air filters with an extremely high collecting efficiency were required for above specific areas.

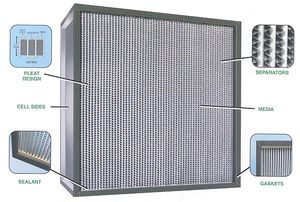

The Absulule (HEPA) Filter consist of frame in which the media is inserted is highly folded form. The filers are held open by corrugated sepearators. The media is produced from highly waler repellent and temperature resistant 100% microglass, High Strength fiber paper. The folded configuration provides an exceptionly large fltering area in proportion to the face area of the filter.Separator design that provides significant advantage controlled media sparing for virtully no turbulance low friction uniform velocity, uniform dust holding optimum filter performance.

The air velocity through the media is very low, normally abot 2-2.5 cm/sec. The seperators are safe edge tapered aluminum or plastic. The absolutes are supplied as standard with gasket of either closed cell neoprene are if desired and at on extra charge with silicon gasket. The gaskets are provided at air entry side and air exit side.

Working Principle

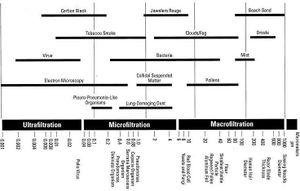

Absolute filters are like conventional fabric filters with small pores at the surface (e.g. a layer of PFTE membrane). Dust particles are collected only by the sieve effect at the outer surface of the filter, due to the very small size of the outer pores, leading to very high efficiencies. They are classified by their minimum collection efficiency. HEPA (High Efficiency Particulate Air) filters have by definition a removal efficiency of more than 99.97% for particles of 0.3μm. ULPA (Ultra Low Penetration Air) filters have by definition a removal efficiency of more than 99.9995% for particles of 0.12μm. Some extended media filters are capable of much higher efficiencies. The collection efficiency increases with increasing filtration velocity and particle size and with dust cake thickness and density. Both types of filters have overall efficiencies that vary with particulate loading.

Application areas

These filters are used for-

Nuclear Instalation Clean - Room Systems

Pharmaceutical industry

Laminar Flow Working Bench

Hospital Sterile areas

Space application

Food processing zone

Biological Center and so on.

Types

Single filters and strainers. Dual-duplex filters and strainers. Manual and fully automatic filters and strainers. Gravity, medium and high pressure filters to 10,000 psig Vacuum pump inlet filters and exhaust filters. Instrumentation protection filters. Cartridge filters. Specialist membrane and coalescing filters for gases and high purity air requirements.

Related topic

Video