Difference between revisions of "Aero Mechanical Conveyors"

m |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Pneumatic Transport]]{{Knoppen}} | [[Category:Pneumatic Transport]]{{Knoppen}} | ||

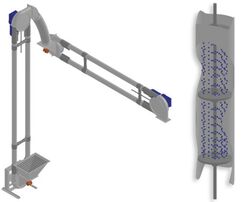

[[File: | [[File:Aero_Mechanical_Conveyor.jpg|thumb|250px|right|Aero Mechanical Conveyor]] | ||

An '''Aero Mechanical Conveyor''' (AMC) is a type of tubular conveyor that uses a cable and disc assembly to transport materials in a fluidized state. It is one of the most efficient methods of conveying materials based on energy consumption per unit mass. | An '''Aero Mechanical Conveyor''' (AMC) is a type of tubular conveyor that uses a cable and disc assembly to transport materials in a fluidized state. It is one of the most efficient methods of conveying materials based on energy consumption per unit mass. | ||

| Line 7: | Line 7: | ||

An AMC consists of three main components: | An AMC consists of three main components: | ||

# A '''loading zone''' where the material is fed into the conveyor by a dispenser or a hopper. | |||

# A '''conveying tube''' where the material is carried by a cable and disc assembly that runs at high speed. The discs are made of antistatic plastic material and are spaced at regular intervals on the cable. The discs create small suction chambers that fluidize the material and prevent segregation or degradation of the product. | |||

# An '''unloading zone''' where the material is discharged by centrifugal force through an outlet. | |||

The AMC operates at any angle from 0° to 90° without loss of capacity¹⁴. It can also convey materials vertically and horizontally within the same unit, or around corners by using specially designed sprockets¹. The AMC can have multiple inlets and outlets to allow for flexible system layout¹⁴. | The AMC operates at any angle from 0° to 90° without loss of capacity¹⁴. It can also convey materials vertically and horizontally within the same unit, or around corners by using specially designed sprockets¹. The AMC can have multiple inlets and outlets to allow for flexible system layout¹⁴. | ||

| Line 17: | Line 17: | ||

The AMC offers several advantages over other types of conveyors, such as: | The AMC offers several advantages over other types of conveyors, such as: | ||

* High throughput: The AMC can operate at speeds up to 36 ft3/min or 2,160 ft3/hour / 1 m3/min or 61 m3/hr with many products. | |||

* Total transfer: The AMC can completely empty the conveying tube without leaving any residue or waste. | |||

* Gentle conveying: The AMC can handle fragile, cohesive, or abrasive materials without causing damage or wear. | |||

* Dust-free conveying: The AMC is totally enclosed and sealed, preventing any dust emission or contamination. | |||

* Low power consumption: The AMC requires less energy than pneumatic conveyors or other mechanical conveyors. | |||

The AMC can be used for various applications that require fast and efficient conveying of powders, granules, flakes, or pellets. Some examples are: | The AMC can be used for various applications that require fast and efficient conveying of powders, granules, flakes, or pellets. Some examples are: | ||

* Food processing: The AMC can convey flour, sugar, salt, spices, coffee, cereals, snacks, etc. | |||

* Chemical industry: The AMC can convey pigments, resins, fertilizers, detergents, etc. | |||

* Pharmaceutical industry: The AMC can convey tablets, capsules, powders, etc. | |||

* Plastic industry: The AMC can convey pellets, flakes, granules, etc. | |||

* Mineral industry: The AMC can convey cement, lime, gypsum, sand, etc. | |||

Latest revision as of 04:41, 16 May 2023

An Aero Mechanical Conveyor (AMC) is a type of tubular conveyor that uses a cable and disc assembly to transport materials in a fluidized state. It is one of the most efficient methods of conveying materials based on energy consumption per unit mass.

Design and operation

An AMC consists of three main components:

- A loading zone where the material is fed into the conveyor by a dispenser or a hopper.

- A conveying tube where the material is carried by a cable and disc assembly that runs at high speed. The discs are made of antistatic plastic material and are spaced at regular intervals on the cable. The discs create small suction chambers that fluidize the material and prevent segregation or degradation of the product.

- An unloading zone where the material is discharged by centrifugal force through an outlet.

The AMC operates at any angle from 0° to 90° without loss of capacity¹⁴. It can also convey materials vertically and horizontally within the same unit, or around corners by using specially designed sprockets¹. The AMC can have multiple inlets and outlets to allow for flexible system layout¹⁴.

Advantages and applications

The AMC offers several advantages over other types of conveyors, such as:

- High throughput: The AMC can operate at speeds up to 36 ft3/min or 2,160 ft3/hour / 1 m3/min or 61 m3/hr with many products.

- Total transfer: The AMC can completely empty the conveying tube without leaving any residue or waste.

- Gentle conveying: The AMC can handle fragile, cohesive, or abrasive materials without causing damage or wear.

- Dust-free conveying: The AMC is totally enclosed and sealed, preventing any dust emission or contamination.

- Low power consumption: The AMC requires less energy than pneumatic conveyors or other mechanical conveyors.

The AMC can be used for various applications that require fast and efficient conveying of powders, granules, flakes, or pellets. Some examples are:

- Food processing: The AMC can convey flour, sugar, salt, spices, coffee, cereals, snacks, etc.

- Chemical industry: The AMC can convey pigments, resins, fertilizers, detergents, etc.

- Pharmaceutical industry: The AMC can convey tablets, capsules, powders, etc.

- Plastic industry: The AMC can convey pellets, flakes, granules, etc.

- Mineral industry: The AMC can convey cement, lime, gypsum, sand, etc.