Difference between revisions of "Agglomerators"

Jump to navigation

Jump to search

| Line 10: | Line 10: | ||

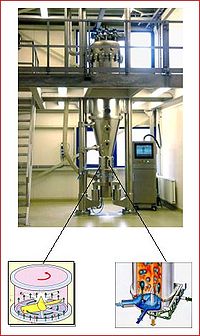

[[Image:Batch_Agglomerator.jpg|thumb|200px|Batch Agglomerator]] | [[Image:Batch_Agglomerator.jpg|thumb|200px|Batch Agglomerator]] | ||

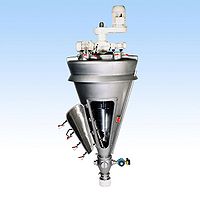

[[Image:Continuous_Agglomerator.jpg|thumb|200px|Continuous Agglomerator]] | [[Image:Continuous_Agglomerator.jpg|thumb|200px|Continuous Agglomerator]] | ||

'''Agglomeration''' describes a process whereby powders get into contact with one or more liquids to create a perfect mixture of powder and liquid in order to make agglomerates. | |||

Less liquid > small agglomerates. | Less liquid > small agglomerates. | ||

Revision as of 14:40, 13 December 2011

Agglomeration describes a process whereby powders get into contact with one or more liquids to create a perfect mixture of powder and liquid in order to make agglomerates.

Less liquid > small agglomerates.

More liquid > larger agglomerates.

To form or collect into a rounded mass Synonyms: granulation, particle size enlargement The perfect Mixers/Agglomerator From the first moment on, the product to be agglomerated is combined with liquid in exactly the correct proportion.

Agglomeration processes or in a more general term particle size enlargement technologies are great tools to modify product properties.

Agglomeration of powders is widely used to improve physical properties like:

- Wettability and dispersability

- Flowability bulk density

- Dosing

- Product appearance

Types

- Batch Agglomerators

- Continuous Agglomerators

Technologies

- Wet agglomeration by instant mixing & fluidbed drying

- Fluidbed agglomeration (batch/continuous)

- Dry granulation by mechanical compaction Low / medium pressure extrusion: e.g. Bextruder / Extrud-O-Mix Spheronization