Banana Screens

The term banana screen can be deceiving. If one were to search the internet looking for “banana screen”, inevitably one would stumble on that yellow fruit with that distinctive shape or a screen saver with that name. Or, one could get links to websites of different manufacturers of this processing equipment.

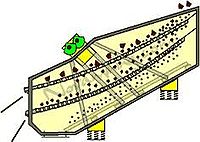

It is that distinctive shape that gave the multi-sloped screen the name “banana”. In industry, the “banana” term is used interchangeably with “multi-sloped”,That European manufacturer later set up their own offices in Australia and I began doing marketing communication work for that company in the mid 90s. Used in wet and dry applications, banana screens are vibratory equipment which use the distinctive shape to process larger volumes of material using a smaller footprint. This is compared to inclined horizontal screens, which as the name implies are horizontal and donʼt have the banana shape. Screens, including banana screens, are used in mining and mineral processing industries. Used in different stages of the process cycle, in either wet or dry applications, the objective of using these equipment is to group together a specific mineral-size fractions, while reducing the the amount of fines carried over with the oversized material.

Improper screening means that there will be a high amount of fines that will remain with the oversized material. This results in high recirculation volumes and greater wear of downstream process equipment. As well, lost production due to downtime is a possibility. The result of proper screening is less crusher wear, less unnecessary recirculation and of course, lower production costs. The points at which screens are used depends on the mineral/ore mined, the nature of the processing plant, the different components of that plant, desired final product and so on. These screens come in a range of sizes and can be built as single or double deck units. They are used more commonly to size ore at one of the stages (primary, secondary, tertiary, quarternary) for further processing. In Australia, banana screens have found a lot use in coal processing. They are widely used for mineral recovery and scalping. Being multislope, they offer higher screening capacity as mentioned earlier. The also are good for recovery in feeds with a very high percentage of near-sized material.

In the coal industry, banana screens are normally used in the second, third or fourth stages of processing plants. To separate material, banana screens use different media. Choice of media, e.g., woven wire, rubber, polyurethane, is guided by the ore/material being processed, the tonnage of throughput and so on.

Video