Difference between revisions of "Batch Agglomerators"

Lavetannpl (talk | contribs) |

|||

| (2 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Particle Formation]]{{Knoppen}} | [[Category:Particle Formation]]{{Knoppen}} | ||

| Line 23: | Line 14: | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

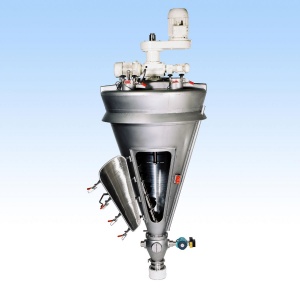

[[File:Continuous Agglomerator.jpg|thumb|right|Batch Agglomerator]] | |||

'''Agglomerators''' are used to increase the particle size of powders. They are very useful for powders of different particle sizes and/or densities that would otherwise seperate when handled. They are used when minor ingredients, often expensive ingredients, must be uniform throughtout a powder. | |||

There are two basic types of agglomerators; compaction and noncompaction. The compaction type uses mechanical pressure (and often very high pressures) to "press" the powders together. For these, binders are sometimes not needed to make the particle. Compaction agglomerators are highly specialized, and not addressed here. | |||

Any system that consists of at least one powder of any size, or mixture of sizes, and a liquid binder are agglomeration candidates. | |||

Agglomerators keep the powders mixing while spraying a binding liquid. The binder is sprayed and then dries or sets or cures or otherwise hardens sealing the powders into a single bead. The need to keep the powders well mixed usually works against the idea of agglomeration. [[Mixers]] use high shear for mixing. This high shear also breaks particles down rather then agglomerates them. Ed O'Brien came up with the idea of a gentle mixing within his agglomerator in the 1960s. | |||

==Process== | ==Process== | ||

# The requested production capacities are normally in the range between 1000 and 4000 kg/hr. | |||

# Process is always batch, with significant variations in recipes. This automatically results in easy and fast cleaning intervals geared to preventing taste and smell contaminations. | |||

# The mixing process has to guarantee a low energy input per kg produced product, resulting in visually acceptable quality, without damaging components in the mixture. | |||

# The complete process normally consists of two separate mixing processes. One is the intensive bulk mixing process (starch, salt, fat), the other is the gentle post mixing process of this bulk with the dedicated fragile specific soup components (vegetables, mushrooms, vermicelli, etc). The first intensive mixing process is executed in paddle or plough shear mixers, the second gentle mixing process is typically done in a Vrieco Nauta mixer. | |||

==Video== | ==Video== | ||

<youtube>SDU-6k4NmFg</youtube> | |||

<youtube> | |||

Latest revision as of 20:38, 7 August 2012

Agglomerators are used to increase the particle size of powders. They are very useful for powders of different particle sizes and/or densities that would otherwise seperate when handled. They are used when minor ingredients, often expensive ingredients, must be uniform throughtout a powder.

There are two basic types of agglomerators; compaction and noncompaction. The compaction type uses mechanical pressure (and often very high pressures) to "press" the powders together. For these, binders are sometimes not needed to make the particle. Compaction agglomerators are highly specialized, and not addressed here.

Any system that consists of at least one powder of any size, or mixture of sizes, and a liquid binder are agglomeration candidates.

Agglomerators keep the powders mixing while spraying a binding liquid. The binder is sprayed and then dries or sets or cures or otherwise hardens sealing the powders into a single bead. The need to keep the powders well mixed usually works against the idea of agglomeration. Mixers use high shear for mixing. This high shear also breaks particles down rather then agglomerates them. Ed O'Brien came up with the idea of a gentle mixing within his agglomerator in the 1960s.

Process

- The requested production capacities are normally in the range between 1000 and 4000 kg/hr.

- Process is always batch, with significant variations in recipes. This automatically results in easy and fast cleaning intervals geared to preventing taste and smell contaminations.

- The mixing process has to guarantee a low energy input per kg produced product, resulting in visually acceptable quality, without damaging components in the mixture.

- The complete process normally consists of two separate mixing processes. One is the intensive bulk mixing process (starch, salt, fat), the other is the gentle post mixing process of this bulk with the dedicated fragile specific soup components (vegetables, mushrooms, vermicelli, etc). The first intensive mixing process is executed in paddle or plough shear mixers, the second gentle mixing process is typically done in a Vrieco Nauta mixer.

Video