Difference between revisions of "Bin Vent Filters"

Jump to navigation

Jump to search

(Created page with "Category:Filtration{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improp...") |

|||

| (2 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Filtration]]{{Knoppen}} | [[Category:Filtration]]{{Knoppen}} | ||

[[File:Bin_Vent_Filters_01.jpg|thumb|right|Bin Vent Filter]] | |||

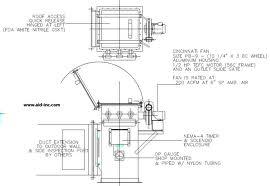

* | [[File:Bin_Vent_Filters_02.jpg|thumb|right|Design of Bin Vent Filters]] | ||

* | [[File:Bin_Vent_Filters_03.JPG|thumb|right|Large Bin Vent Filters]] | ||

* | '''Bin Vent Filters''' are used on the top of Storage Hoppers, Bins, and Silos for venting during refill and unloading. Airborne Dust Particles are arrested by the media during venting. | ||

* | |||

* | Units are available with optional features: | ||

* | *Normally aspirated | ||

*Fan assisted | |||

*Pulsed Air Jet Cleaning features. | |||

Different types of filter media are available to suit the material characteristics, temperature, moisture content and other application. The [[Filter Cartridges]] are of replaceable types with easy removable designs. Several material of constructions like needle punched Polyester, Non woven , Felt, PTFE membrane of non-stick, water, oil repellant properties having B.I.A rating U.S.G.C.. | |||

==Features== | |||

*High Efficiency - Filter media removes 99.99+ % of entrained particles. | |||

*Low Energy Requirements - Compressed air usage is minimized through precise matching of cleaning requirements and cleaning frequency. | |||

*Low Maintenance Requirements - No moving parts inside the collector. Pulsing system can be inspected without shutting down the collector. | |||

*Quick Installation - Welded housing is shipped ready to install. Collector may be mounted directly to the bin or silo, or supplied with a hopper and support legs as a freestanding unit. | |||

*Quality, Economy, Dependability | |||

==Application area== | |||

*Chemical processing | |||

*Plastics and petrochemicals | |||

*Food and dairy | |||

*Paint and pigments | |||

*Mining and minerals | |||

*Cement and rock products | |||

*Coal and fly ash | |||

*Pharmaceutical | |||

==Video== | |||

<youtube>JqPTY_0W5AI</youtube> | |||

Latest revision as of 01:05, 18 February 2013

Bin Vent Filters are used on the top of Storage Hoppers, Bins, and Silos for venting during refill and unloading. Airborne Dust Particles are arrested by the media during venting.

Units are available with optional features:

- Normally aspirated

- Fan assisted

- Pulsed Air Jet Cleaning features.

Different types of filter media are available to suit the material characteristics, temperature, moisture content and other application. The Filter Cartridges are of replaceable types with easy removable designs. Several material of constructions like needle punched Polyester, Non woven , Felt, PTFE membrane of non-stick, water, oil repellant properties having B.I.A rating U.S.G.C..

Features

- High Efficiency - Filter media removes 99.99+ % of entrained particles.

- Low Energy Requirements - Compressed air usage is minimized through precise matching of cleaning requirements and cleaning frequency.

- Low Maintenance Requirements - No moving parts inside the collector. Pulsing system can be inspected without shutting down the collector.

- Quick Installation - Welded housing is shipped ready to install. Collector may be mounted directly to the bin or silo, or supplied with a hopper and support legs as a freestanding unit.

- Quality, Economy, Dependability

Application area

- Chemical processing

- Plastics and petrochemicals

- Food and dairy

- Paint and pigments

- Mining and minerals

- Cement and rock products

- Coal and fly ash

- Pharmaceutical

Video