Classifier Mills

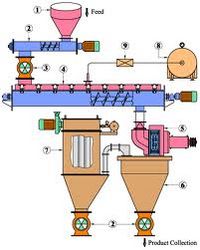

Classifier Mills (CLM) offers the combination of two-stage closed circuit grinding with interstage air classification all in one convenient unit. When faced with materials that can be difficult to grind or that require a narrower particle distribution curve, the unique capabilities of the classifier mill are often necessary. Large access doors on the classifier mills allow for quick inspection or cleaning of the main rotor and classifier rotor.

Classifier mills are ideal for difficult to grind applications or narrow particle distribution curve requirements, and offers simple maintenance, uniform particle distribution, screen-less screen frame that prevents screen damage and wear and, lastly, a secondary inlet to provide additional air for an element of cooling.

Stages

Initial Grinding Stage

Using the secondary inlet, additional air adds a cooling element to the material being processed.

Particle Rejection Stage

Particles that are larger than specified are rejected by the classifier and directed into the third stage.

Final Stage

These particles go into a separate part of the grinding rotor designed specifically for difficult-to-grind pieces. This material is then directed to the classifier, which allows only properly-sized product to exit the machine.

Video