Difference between revisions of "Cooling Screws"

Jump to navigation

Jump to search

m |

|||

| Line 1: | Line 1: | ||

[[Category:Screw Conveying]]{{Knoppen}} | [[Category:Screw Conveying]]{{Knoppen}} | ||

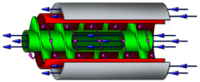

[[File:Cooling_screws.jpg|200px|thumb|right|Cooling Screws]] | [[File:Cooling_screws.jpg|200px|thumb|right|Cooling Screws]] | ||

[[File:Cooling_screws1.png|200px|thumb|right|Cooling Screws | [[File:Cooling_screws1.png|200px|thumb|right|Cooling Screws heat diagram]] | ||

'''Cooling Screws''' serve a double objective. They transport solids or liquids and lower the temperature at the same time. In a sense the [[Conveyor Screws|conveyor screw]] can work as a [[Heat Exchangers|heat exchanger]]. | |||

==Advantages== | ==Advantages== | ||

* Designs for high pressure applications meet the requirements of the ASME Boiler and Pressure Vessel Code. | * Designs for high pressure applications meet the requirements of the ASME Boiler and Pressure Vessel Code. | ||

| Line 25: | Line 10: | ||

* Control of temperature during material transfer. | * Control of temperature during material transfer. | ||

Cooling screws are capable of handling the high pressures associated with ice thermal storage or heat pump applications with the highest available efficiencies and reducing the refrigerant charge up to 30% and utility emissions as much as 30%. | |||

Latest revision as of 22:09, 14 April 2013

Cooling Screws serve a double objective. They transport solids or liquids and lower the temperature at the same time. In a sense the conveyor screw can work as a heat exchanger.

Advantages

- Designs for high pressure applications meet the requirements of the ASME Boiler and Pressure Vessel Code.

- Cost savings as the thermal treatment is accomplished in the same time as product is conveyed.

- Accurate control of thermal treatment time.

- Control of temperature during material transfer.

Cooling screws are capable of handling the high pressures associated with ice thermal storage or heat pump applications with the highest available efficiencies and reducing the refrigerant charge up to 30% and utility emissions as much as 30%.