Diesel Engines

Diesel Engine also known as a compression-ignition engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber. This is in contrast to spark-ignition engines such as a petrol engine or gasoline engine or gas engine , which uses a spark plug to ignite an air-fuel mixture. The engine was developed by Rudolf Diesel in 1893.

The diesel engine has the highest thermal efficiency of any regular internal or external combustion engine due to its very high compression ratio. Low-speed diesel engines as used in ships and other applications where overall engine weight is relatively unimportant can have a thermal efficiency that exceeds 50%.

Diesel engines are manufactured in two-stroke and four-stroke versions. They were originally used as a more efficient replacement for stationary steam engines. Since the 1910s they have been used in submarines and ships. Use in locomotives, trucks, heavy equipment and electric generating plants followed later. In the 1930s, they slowly began to be used in a few automobiles. Since the 1970s, the use of diesel engines in larger on-road and off-road vehicles in the USA increased. As of 2007, about 50% of all new car sales in Europe are diesel.

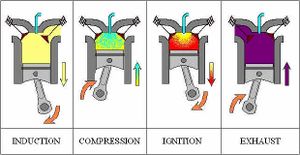

How diesel engines work

The diesel internal combustion engine differs from the gasoline powered Otto cycle by using highly compressed hot air to ignite the fuel rather than using a spark plug In the true diesel engine, only air is initially introduced into the combustion chamber. The air is then compressed with a compression ratio typically between 15:1 and 22:1 resulting in 40-bar pressure compared to 8 to 14 bars in the petrol engine. This high compression heats the air to 550 °C (1,022 °F). At about the top of the compression stroke, fuel is injected directly into the compressed air in the combustion chamber. This may be into a void in the top of the piston or a pre-chamber depending upon the design of the engine. The fuel injector ensures that the fuel is broken down into small droplets, and that the fuel is distributed evenly. The heat of the compressed air vaporizes fuel from the surface of the droplets. The vapour is then ignited by the heat from the compressed air in the combustion chamber, the droplets continue to vaporise from their surfaces and burn, getting smaller, until all the fuel in the droplets has been burnt. The start of vaporisation causes a delay period during ignition and the characteristic diesel knocking sound as the vapour reaches ignition temperature and causes an abrupt increase in pressure above the piston. The rapid expansion of combustion gases then drives the piston downward, supplying power to the crankshaft. Engines for scale-model aeroplanes use a variant of the diesel principle but premix fuel and air via a carburation system external to the combustion chambers.

As well as the high level of compression allowing combustion to take place without a separate ignition system, a high compression ratio greatly increases the engine's efficiency. Increasing the compression ratio in a spark-ignition engine where fuel and air are mixed before entry to the cylinder is limited by the need to prevent damaging pre-ignition. Since only air is compressed in a diesel engine, and fuel is not introduced into the cylinder until shortly before top dead centre (TDC), premature detonation is not an issue and compression ratios are much higher.

Advantages

Diesel engines have several advantages over other internal combustion engines:

- They burn less fuel than a petrol engine performing the same work, due to the engine's higher temperature of combustion and greater expansion ratio.[1] Gasoline engines are typically 30% efficient while diesel engines can convert over 45% of the fuel energy into mechanical energy.

- They have no high voltage electrical ignition system, resulting in high reliability and easy adaptation to damp environments. The absence of coils, spark plug wires, etc., also eliminates a source of radio frequency emissions which can interfere with navigation and communication equipment, which is especially important in marine and aircraft applications.

- The life of a diesel engine is generally about twice as long as that of a petrol engine due to the increased strength of parts used. Diesel fuel has better lubrication properties than petrol as well.

- Diesel fuel is distilled directly from petroleum. Distillation yields some gasoline, but the yield would be inadequate without catalytic reforming, which is a more costly process.

- Diesel fuel is considered safer than petrol in many applications. Although diesel fuel will burn in open air using a wick, it will not explode and does not release a large amount of flammable vapor. The low vapor pressure of diesel is especially advantageous in marine applications, where the accumulation of explosive fuel-air mixtures is a particular hazard. For the same reason, diesel engines are immune to vapor lock.

- For any given partial load the fuel efficiency of a diesel engine remains nearly constant, as opposed to petrol and turbine engines which use proportionally more fuel with partial power outputs.

- They generate less waste heat in cooling and exhaust.

- Diesel engines can accept super-or turbo-charging pressure without any natural limit, constrained only by the strength of engine components. This is unlike petrol engines, which inevitably suffer detonation at higher pressure.

- The carbon monoxide content of the exhaust is minimal, therefore diesel engines are used in underground mines.

- Biodiesel is an easily synthesized, non-petroleum-based fuel which can run directly in many diesel engines, while gasoline engines either need adaptation to run synthetic fuels or else use them as an additive to gasoline .