Difference between revisions of "Direct Heated Dryers"

| Line 6: | Line 6: | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Direct_Heated_Dryers.jpg|thumb|200px|right|Direct Heated Dryers]] | [[File:Direct_Heated_Dryers.jpg|thumb|200px|right|Direct Heated Dryers]] | ||

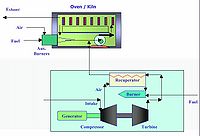

The '''Direct Heated Dryers''' follow the direct heating or drying process. This Direct heating and drying refers to combustion products mixing directly with the process environment (typically process solids and a forced “air” stream). Because radiation transfer is rapid, typically at high temperature, and ceases upon reaching a boundary (the outer layer of process matter), it is often undesirable and unnecessary. Therefore, natural and forced convection heat transfer engineering may dominate dryer designs. There are a wide variety of process dryers, kilns, calciners, ovens, etc. that incorporate an even greater range of combinations in forced convection, radiation, and conduction (through the material) heat transfer principles to satisfy the product requirements. | |||

==='''Functions'''=== | |||

In all cases, however, the heat energy supplied to a system must perform the following four tasks: | |||

* Heat the dryer feed to the “light” component’s vaporization temperature. | |||

* | * Vaporize and/or free the liquid/byproducts above the solids’ surface. | ||

* Heat the solids to the final desired temperature, and for the desired duration of time. | |||

* Heat the vapor to the final desired temperature. | |||

* | |||

* | |||

* | |||

Revision as of 10:26, 1 August 2012

The Direct Heated Dryers follow the direct heating or drying process. This Direct heating and drying refers to combustion products mixing directly with the process environment (typically process solids and a forced “air” stream). Because radiation transfer is rapid, typically at high temperature, and ceases upon reaching a boundary (the outer layer of process matter), it is often undesirable and unnecessary. Therefore, natural and forced convection heat transfer engineering may dominate dryer designs. There are a wide variety of process dryers, kilns, calciners, ovens, etc. that incorporate an even greater range of combinations in forced convection, radiation, and conduction (through the material) heat transfer principles to satisfy the product requirements.

Functions

In all cases, however, the heat energy supplied to a system must perform the following four tasks:

- Heat the dryer feed to the “light” component’s vaporization temperature.

- Vaporize and/or free the liquid/byproducts above the solids’ surface.

- Heat the solids to the final desired temperature, and for the desired duration of time.

- Heat the vapor to the final desired temperature.