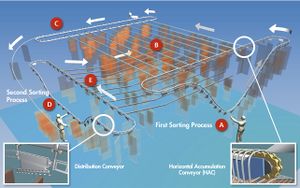

Distributing Conveyors

Distributing Conveyors provides controlled, quiet delivery of product to various processing, packaging and discharge points in the system with below-bed or overhead installation.

Dependent on the number of aggregate bins of the plant, a distributing conveyor is placed at the top of the bins to ensure the correct material gets placed in the right aggregate bin.For instance when in-line or square bins are used a turntable console and a reversible distributing conveyor allows precise and easy filling of aggregates possible. The equipment typically consists of a centrally placed, cylindrical base on which a turntable steel frame is rested. The belt is supported by a flat iron ring installed on the platform of the bin. This design is of course hot-galvanized in order for the design to have a long lifetime. The equipment varies according to the task, but high quality and low maintenance is again paramount for all solutions.

Functions

- conveying

- merging

- queuing

- distributing

Fields of Application

- Sorting lines in box & bin conveying systems

- Packaging&palletizing systems

- Distribution centres, logistics/parcel and industrial trade services

- Printing and book binding industries and dry areas in food an pharmacy industries

- Materials handling integrators and OEMs

Technical Advantages

- One unit offering four functions:conveying, merging queuing, distributing easily adjustable to handle different loads

- A highly economical sortation system

- Power efficient; needing just 1 drive for 10 metres of track and four divert units

- Space efficient being of smooth compact design with no protrusion

- Slow noise emission