Dosing Screws

Dosing Screws units can be supplied as volumetric feeders where a variable speed drive is used to change the dosing rate. Alternatively loadcells can be integrated into the system to provide accurate loss in weight feed of material. For extreme turndown ratios the electric drive motor can be supplied with a cooling fan.

A horizontal paddle above the dosing screw ensures that the material is evenly fed into the dosing screw. This allows accurate feeding of the most difficult materials. Paddle types are selected according to the material fed through the dosing screw. On the standard version the paddle is driven via the screw shaft with a chain and chain tensioner. Alternatively the paddle shaft and screw shaft can be driven independently by two geared motors. Dosing screws can be fitted with manual dump hoppers or the inlet hopper sized and designed for automatic refilling – either by using level sensors to control the head of material or by using the integrated loadcells on the loss in weight system.

Both the driven and non-driven ends of the paddle and the driven end of the dosing screw are fitted with stuffing glands to ensure a dust tight sealing arrangement. The outboard bearings are mounted on standoffs to allow easy access to the stuffing gland while the bearings on the driven end are housed under the gear and chain guard.

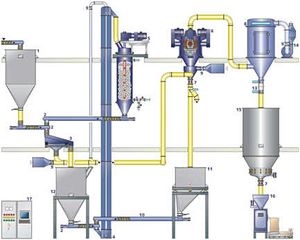

Functional Principle

The bulk material enters the second screw via the product inlet of the first screw and is then transferred to the screw outlet. The metering screw is activated and rotates picking up product and conveying it uniformly to the screw outlet. The frequency control of the drive changes over from coarse to fine metering in metering and weighing operations. This means that the speed of the metering screw is reduced correspondingly. When the set weight has been reached, a pneumatically operated shutoff valve closes the screw outlet.

Uses

For continuous and discontinuous conveying and metering of bulk materials in several conveying lines and scales etc.

- Plastic industry

- Food industry

- Chemical industry

- Bulk solids