Difference between revisions of "Fine Particle Mills"

(Created page with "Category:Particle Size Reduction{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the c...") |

PurplePen19 (talk | contribs) |

||

| Line 5: | Line 5: | ||

* Please do not edit the sponsored link on the top right corner. . | * Please do not edit the sponsored link on the top right corner. . | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

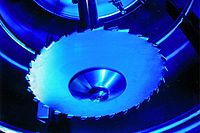

[[File:Fine Particle Mills_1.jpg|thumb|200px|right|Fine Particle Mills]] | |||

[[File:Fine Particle Mills_2.jpg|thumb|200px|right|Fine Particle Mills Cutter]] | |||

'''Fine Particle Mills''' are used for fine milling of materials. products. The mill is suited to reducing friable or fragile and breakable materials — that is, any material that breaks rather than flattens under pressure — in applications that require a uniform particle size with minimal fines. | |||

==Operations== | |||

In operation, the feeding device gravity-feeds material at a constant rate to the roll gap between the top pair of rolls. The material enters the nip point (where the gap between the rolls is smallest) and is crushed into smaller particles as the rolls counter-rotate. If the mill has multiple roll pairs, the reduced particles will fall into the next pair’s nip point, be crushed into smaller particles, and pass to the next roll pair, until the desired- size particles are discharged by gravity from the bottom roll pair. | |||

==Video== | |||

<youtube>iNG04oJQyBY</youtube> | |||

Latest revision as of 07:47, 12 October 2012

Fine Particle Mills are used for fine milling of materials. products. The mill is suited to reducing friable or fragile and breakable materials — that is, any material that breaks rather than flattens under pressure — in applications that require a uniform particle size with minimal fines.

Operations

In operation, the feeding device gravity-feeds material at a constant rate to the roll gap between the top pair of rolls. The material enters the nip point (where the gap between the rolls is smallest) and is crushed into smaller particles as the rolls counter-rotate. If the mill has multiple roll pairs, the reduced particles will fall into the next pair’s nip point, be crushed into smaller particles, and pass to the next roll pair, until the desired- size particles are discharged by gravity from the bottom roll pair.

Video