Difference between revisions of "Grate Coolers"

(Created page with "Category:Cooling{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improper ...") |

|||

| Line 1: | Line 1: | ||

[[ | |||

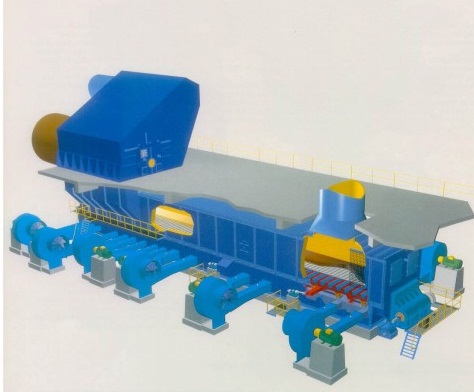

[[File:Grate cooler.jpg]] | |||

This | |||

Early systems used rotary coolers, which were rotating cylinders similar to the kiln, into which the hot clinker dropped.The combustion air was drawn up through the cooler as the clinker moved down, cascading through the air stream. In the 1920s, satellite coolers became common and remained in use until recently. These consist of a set of tubes attached to the kiln tube. They have the advantage that they are sealed to the kiln, and require no separate drive. From about 1930, the grate cooler was developed. This consists of a perforated grate through which cold air is blown, enclosed in a rectangular chamber. A bed of clinker up to 0.5 m deep moves along the grate. These coolers have two main advantages: they cool the clinker rapidly, which is desirable from a quality point of view (to avoid that alite, thermodynamically unstable below 1250 °C, revert to belite and free CaO on slow cooling), and, because they do not rotate, hot air can be ducted out of them for use in fuel drying, or for use as precalciner combustion air. The latter advantage means that they have become the only type used in modern systems. | |||

Revision as of 12:55, 28 July 2012

Early systems used rotary coolers, which were rotating cylinders similar to the kiln, into which the hot clinker dropped.The combustion air was drawn up through the cooler as the clinker moved down, cascading through the air stream. In the 1920s, satellite coolers became common and remained in use until recently. These consist of a set of tubes attached to the kiln tube. They have the advantage that they are sealed to the kiln, and require no separate drive. From about 1930, the grate cooler was developed. This consists of a perforated grate through which cold air is blown, enclosed in a rectangular chamber. A bed of clinker up to 0.5 m deep moves along the grate. These coolers have two main advantages: they cool the clinker rapidly, which is desirable from a quality point of view (to avoid that alite, thermodynamically unstable below 1250 °C, revert to belite and free CaO on slow cooling), and, because they do not rotate, hot air can be ducted out of them for use in fuel drying, or for use as precalciner combustion air. The latter advantage means that they have become the only type used in modern systems.