Gravimetric Dosing Systems

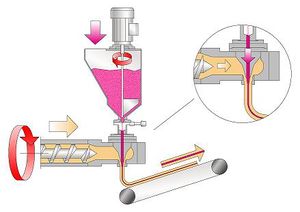

Gravimetric Dosing System is an advanced technology for the continuous blending of materials at the highest level of accuracy. In gravimetric dosing (blending) the primary material being extruded is accurately weighed in a free flowing hopper located directly above the extruder feed throat. Additive materials are continuously weighed and auger fed or Dosed into the primary material flow at a preselected percentage by weight of total output. This highly effective technique virtually eliminates premixed material volume and with it the possibility for segregation and demixing of the blend. Continuous gravimetric dosing systems facilitate rapid product changeover, minimizing the cost of job changes by reducing production loss and scrap generation.

Gravimetric Dosing system is a flexible and interchangeable laboratory reactor system. Pumping a defined reagent from a balance to the reactor through a peristaltic pump, the flow rate can be controlled, monitored and changed .

Gravimetric Dosing benefits

- Quick change vessel: The oil drain unit, jacketed vessel clamp and quick oil connectors allow vessels to be changed in under a minute.

- Automated reactions without PC control: Set points, ramps, or sophisticated profiles are all possible for temperature and stirring.

- Easy to upgrade: A wide range of accessories are available including vessels, stirrers, probes, etc.

- Wide flow rate and mass ranges: 1ml/min to 2 litres/min and up to 4000g.

- Advanced control: Define the mass to be dosed as a set point or sophisticated profile .

- Wide temperature range: -80 to +200°C.

- Easy to use: The Gravimetric Dosing system can be set up quickly and without the need for any tools.

- Robust: Specifically designed for use in chemical laboratories.