Difference between revisions of "Hammer Mills"

(Created page with "Category:Particle Size Reduction{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the ...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

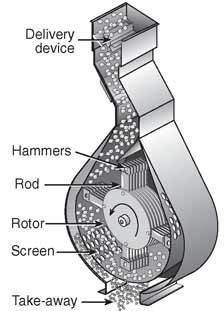

[[File:Hammer_mill1.jpg |thumb| right |Inside view of a Hammer mill. ]] | |||

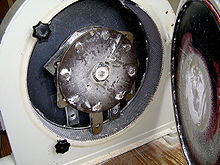

[[File:Hammer_mill2.jpg |thumb| right |Desktop hammer mill used for preparing | |||

growth media in a life sciences laboratory. ]] | |||

[[File:Hammer_mill3.jpg |thumb| right |Hammermill for milling grain ]] | |||

A '''hammermill''' is a machine whose purpose is to shred or crush aggregate material into smaller pieces. These machines have many sorts of applications in many industries, including: | |||

*Ethanol plants (corn) | |||

*A farm machine, which mills grain into coarse flour to be fed to livestock | |||

*Fluff pulp production | |||

*Fruit juice production | |||

*Grinding used shipping pallets for mulch | |||

*Milling grain | |||

*Sawmills, size reduction of trim scrap and planer shavings into boiler fuel or mulch Desktop hammer mill used for preparing growth media in a life sciences laboratory | |||

*Shredding paper | |||

*Shredding scrap automobiles (see automotive shredder residue) | |||

*Shredding yard and garden waste for composting | |||

*Crushing large rocks | |||

*In waste management | |||

==Operation== | |||

The basic principle is straightforward. A hammermill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size. | |||

Small grain hammermills can be operated on household current. Large automobile shredders can use one or more 2000 horsepower (1.5 MW) diesel engines to power the hammermill. | |||

The Screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammermills. | |||

Revision as of 02:54, 3 February 2012

A hammermill is a machine whose purpose is to shred or crush aggregate material into smaller pieces. These machines have many sorts of applications in many industries, including:

- Ethanol plants (corn)

- A farm machine, which mills grain into coarse flour to be fed to livestock

- Fluff pulp production

- Fruit juice production

- Grinding used shipping pallets for mulch

- Milling grain

- Sawmills, size reduction of trim scrap and planer shavings into boiler fuel or mulch Desktop hammer mill used for preparing growth media in a life sciences laboratory

- Shredding paper

- Shredding scrap automobiles (see automotive shredder residue)

- Shredding yard and garden waste for composting

- Crushing large rocks

- In waste management

Operation

The basic principle is straightforward. A hammermill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size.

Small grain hammermills can be operated on household current. Large automobile shredders can use one or more 2000 horsepower (1.5 MW) diesel engines to power the hammermill.

The Screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammermills.