Hydraulic Actuators

Hydraulic Actuators are mechanical Actuators that converts hydraulic pressure and flow into torque and angular displacement. The hydraulic actuator is the rotary counter part of the Hydraulic Cylinders. Conceptually, a hydraulic motor should be interchangeable with a hydraulic pump because it performs the opposite function - much as the conceptual DC electric motor is interchangeable with a DC electrical generator. However, most hydraulic pumps cannot be used as hydraulic actuators because they cannot be back driven. Also, a hydraulic actuator is usually designed for the working pressure at both sides of the motor.Hydraulic pumps, motors, and cylinders can be combined into hydraulic drive systems. One or more hydraulic pumps, coupled to one or more hydraulic actuators , constitutes a hydraulic transmission.

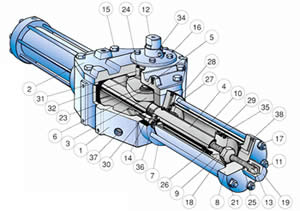

Hydraulic actuators or hydraulic cylinders typically involve a hollow cylinder having a piston inserted in it. An unbalanced pressure applied to the piston provides force that can move an external object. Since liquids are nearly incompressible, a hydraulic cylinder can provide controlled precise linear displacement of the piston. The displacement is only along the axis of the piston. A familiar example of a manually operated hydraulic actuator is a hydraulic car jack. Typically though, the term hydraulic actuator refers to a device controlled by a hydraulic pump.

Uses

Hydraulic actuators are used for many applications now such as winches and crane drives, wheel motors for military vehicles, self-driven cranes, and excavators. Conveyor and feeder drives, mixer and agitator drives, roll mills, drum drives for digesters, trommels and kilns, shredders for cars, tyres, cable and general garbage, drilling rigs, trench cutters, high-powered lawn trimmers.