Hydraulic Cylinders

Hydraulic Cylinder also called a linear hydraulic motor is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in engineering vehicles, industrial application, civil applications.

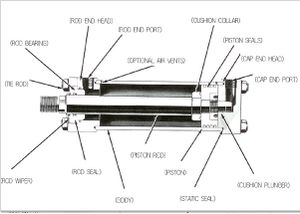

Parts of a hydraulic cylinder

A hydraulic cylinder consists of the following parts:

Cylinder barrel

The main function of cylinder body is to hold cylinder pressure. The cylinder barrel is mostly made from a seamless tube. The cylinder barrel is ground and/or honed internally with a typical surface finish of 4 to 16 microinch. Normally hoop stress are calculated to optimize the barrel size.

Cylinder base or cap

The main function of cap is to enclose the pressure chamber one end. The cap is connected to the body by means of welding, threading, bolts, tie rod. Cap also perform as a cylinder mounting components that is, cap flange, cap trunnion, cap clevis. Cap size determined based on the bending stress. A static seal / o-ring used in between cap and barrel .

Cylinder head

The main function of head is to enclose the pressure chamber from other end. Head contains an integrated rod sealing arrangement or option to accept a seal gland. The head is connected to the body by means of threading, bolts, tie rod. A static seal / o-ring used in between head and barrel.

Piston

The main function of piston is to separate pressure zone in side barrel. The piston is machined with grooves to fit elastomeric or metal seals and bearing elements. These seals can be single acting or double acting. This difference in pressure between the two sides of the piston causes the cylinder to extend and retract. Piston is attached with the piston rod by means of threads, bolts, nuts to transfer the linear motion.

Piston rod

The piston rod is typically a hard chrome-plated piece of cold-rolled steel which attaches to the piston and extends from the cylinder through the rod-end head. In double rod-end cylinders, the actuator has a rod extending from both sides of the piston and out both ends of the barrel. The piston rod connects the Hydraulic Actuators to the machine component doing the work. This connection can be in the form of a machine thread or a mounting attachment.

Seal gland

The cylinder head is fitted with seals to prevent the pressurized oil from leaking past the interface between the rod and the head. This area is called the seal gland. The advantage of seal gland is easy removal and seal replacement. The seal gland contains primary seal, secondary seal or buffer seal, bearing elements, wiper or scraper and static seal. In some cases, especially in small hydraulic cylinders, the rod gland and the bearing elements are made from a single integral machined part.

Seals

The seals are considered or design as per the cylinder working pressure, cylinder speed, operating temperature, working medium and application. Piston seals are dynamic seals, can be single acting or double acting. Generally speaking, Elastomers seals made from nitrile rubber, Polyurethane or other materials are best in lower temperature environments, while seals made of Fluorocarbon Viton are better for higher temperatures. Metallic seals are also available commonly used cast iron for seal material. Rod seal are dynamic seals and generally single acting. The compounds of rod seals are nitrile rubber, Polyurethane, Fluorocarbon Viton. Wiper or scraper are used to eliminates contaminants such as moisture, dirt, and dust, which can cause extensive damage to cylinder walls, rods, seals and other components. The common compound for wiper is polyurethane. Metallic scraper are used for sub zero temperature application, application where foreign material can deposit on rod. The bearing element or wear bands are use to eliminate metal to metal contact. The wear bands are design as per the side load requirements. The primary compounds for wear bands are filled PTFE, Woven fabric reinforced polyester resin, bronze.

Other parts

- Cylinder base connection

- Cushions

Special hydraulic cylinders

Telescopic cylinder

The length of an hydraulic cylinder is the total of the stroke, the thickness of the piston, the thickness of bottom and head and the length of the connections. Often this length does not fit in the machine. In that case the piston rod is also used as a piston barrel and a second piston rod is used. These kinds of cylinders are called telescopic cylinders. If we call a normal rod cylinder single stage, telescopic cylinders are multi-stage units of two, three, four, five or more stages. In general telescopic cylinders are much more expensive than normal cylinders. Most telescopic cylinders are single acting .Double acting telescopic cylinders must be specially designed and manufactured.

Plunger cylinder

An hydraulic cylinder without a piston or with a piston without seals is called a plunger cylinder. A plunger cylinder can only be used as a pushing cylinder; the maximum force is piston rod area multiplied by pressure. This means that a plunger cylinder in general has a relatively thick piston rod.

Differential cylinder

A differential cylinder acts like a normal cylinder when pulling. If the cylinder however has to push, the oil from the piston rod side of the cylinder is not returned to the reservoir, but goes to the bottom side of the cylinder. In such a way, the cylinder goes much faster, but the maximum force the cylinder can give is like a plunger cylinder. A differential cylinder can be manufactured like a normal cylinder, and only a special control is added.

Rephasing cylinder

Rephasing cylinders are two or more cylinders plumbed in series or parallel, with the bores and rods sized such that all rods extend and/or retract equally when flow is directed to the first, or last, cylinder within the system.In parallel applications, the bore and rod sizes are always the same, and the cylinders are always used in pairs. In series applications, the bore and rod sizes are always different, and two or more cylinders may be used. In these applications, the bores and rods are sized such that all rods extend or retract equally when flow is applied to the first or last cylinder within the system.

This hydraulic synchronization of rod positions eliminates the need for a flow divider in the hydraulic system, or any type of mechanical connection between the cylinder rods to achieve synchronization.

Position sensing smart hydraulic cylinder

Position sensing hydraulic cylinders eliminate the need for a hollow cylinder rod. Instead, an external sensing bar using hall-effect technology senses the position of the cylinder’s piston. This is accomplished by the placement of a permanent magnet within the piston. The magnet propagates a magnetic field through the steel wall of the cylinder, providing a locating signal to the sensor.