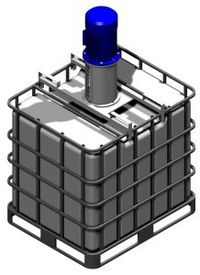

IBC Mixers

IBC Mixers are designed for use with plastic transportable intermediate bulk carrier (IBC) containers. IBC mixers quickly re-suspends product that has settled in transportation or storage. These mixers provide a cost effective solution for products that need to be mixed before use. Using the IBC as a mixing vessel ensures consistent product quality and offers significant cost savings on transfer and cleaning time.

Common Field of Applications

- Chemical Industries

- Dye stuffs & Pigment

- Slurries

- Paint & Varnish

- Food & Beverage

- Water treatment chemicals and flocculants

- Cosmetics Industry

Typical Specifications

The IBC mixer drive is supported on a lightweight stainless steel bridge that mounts directly onto the IBC frame and is secured in place with quick action toggle clamps. As standard, IBC mixers are supplied with an eye bolt for lifting with a hoist or optional fork lift module - for lifting with a fork lift truck.

Common Parts

IBC Electric Motors

380 to 415 volts 3 ph 50 Hz protection IP55 optional 240 v and 110volts 1ph fitted with Start / Stop push buttons and overload relays,A safety interlock is integrated into the mixer support bridge and wired to the motor control to prevent the mixer from being started when not mounted on an IBC. Connection to the unit is with a 4 pin 16 amp plug / socket, Steel wire armoured flex extension cable are available – 3metre 5metre and 10 meter long.

IBC Air Motors

These are fitted with a flow control valve and muffler. Gear Drives Factory filled with a synthetic food quality lubricant and sealed for life.

IBC Shaft and Impellers

The mixer shaft and impellers are manufactured in 316 stainless steel.

High speed IBC mixers can be fitted with single or dual fixed impellers and low speed mixers with folding Impellers.

Video