Difference between revisions of "Industrial Vacuum Machines"

(Created page with "Category:Cleaning{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Cleaning]]{{Knoppen}} | [[Category:Cleaning]]{{Knoppen}} | ||

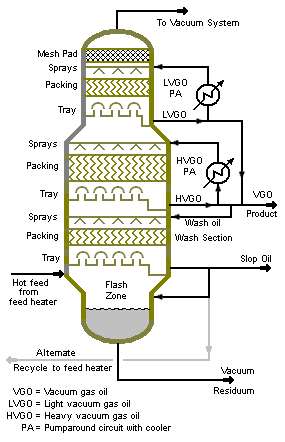

[[File:Industrial_Vacuum_Machines_03.png|thumb|right|Industrial Vacuum Machines common diagram]] | |||

[[File:Industrial_Vacuum_Machines_01.jpg|thumb|right|Industrial Vacuum Machine]] | |||

[[File:Industrial_Vacuum_Machines_02.JPG|thumb|right|Modern Industrial Vacuum Machine]] | |||

The '''Industrial vacuum machines''' boast 100 percent more filter area for increased efficiency, a unique atmospheric blowback system that allows filter cleaning with power on, larger wheels to deliver superior maneuverability, and reduced noise levels, making the 1050 the quietest portable industrial vacuum cleaner in the industry. | |||

* | Two of the most significant improvements are the unit's increased filter capacity which enhances the ability to handle finer powders and filter them more efficiently reducing the load on the vacuum producer, and the new unique atmospheric blowback system. | ||

* - | |||

The reduced load on the vacuum producer puts more power to the end of the hose, giving the operator more power for an extended period of time than in the past. | |||

In the past providing larger filter capacity was a challenge because that meant although the vacuum was electric powered, an umbilical cord to a compressed air supply was necessary to pulse clean the filters. Now, the unique atmospheric blowback system allows users to clean the filters without compressed air and without having to turn off the vacuum increasing productivity and reducing wear and tear on the motor. | |||

Due to the unit's maneuverability and its powerful suction, it can also be used as a portable central vacuum system with one, two or three operators using local tubing networks in multiple areas, supporting a couple hundred feet of tubing. Because the unit is moved to debris it uses less energy than a central vacuum system that requires more hp to move material farther, and costs around half of what a central vacuum system cost. | |||

==Types== | |||

*Wet Dry Vacuums | |||

*Air Operated Vacuums | |||

*Hepa Vacuums | |||

*Continuous Duty Vacuums | |||

*Combustible Dust Vacuums | |||

*Central Vacuum Systems | |||

*Industrial Vacuum Cleaners for Textile | |||

*Liquid Recovery Vacuums | |||

*Flamable Liquid Recovery | |||

*Metalworking Shop Vacuums | |||

*Pharmaceutical Vacuums | |||

*Trim Recovery Vacuums | |||

*Intercept Hoppers and Pre-Separators | |||

*Hose and Tools | |||

==Video== | |||

<youtube>0Sjk0k9DUzY</youtube> | |||

Latest revision as of 04:30, 21 June 2013

The Industrial vacuum machines boast 100 percent more filter area for increased efficiency, a unique atmospheric blowback system that allows filter cleaning with power on, larger wheels to deliver superior maneuverability, and reduced noise levels, making the 1050 the quietest portable industrial vacuum cleaner in the industry.

Two of the most significant improvements are the unit's increased filter capacity which enhances the ability to handle finer powders and filter them more efficiently reducing the load on the vacuum producer, and the new unique atmospheric blowback system.

The reduced load on the vacuum producer puts more power to the end of the hose, giving the operator more power for an extended period of time than in the past.

In the past providing larger filter capacity was a challenge because that meant although the vacuum was electric powered, an umbilical cord to a compressed air supply was necessary to pulse clean the filters. Now, the unique atmospheric blowback system allows users to clean the filters without compressed air and without having to turn off the vacuum increasing productivity and reducing wear and tear on the motor.

Due to the unit's maneuverability and its powerful suction, it can also be used as a portable central vacuum system with one, two or three operators using local tubing networks in multiple areas, supporting a couple hundred feet of tubing. Because the unit is moved to debris it uses less energy than a central vacuum system that requires more hp to move material farther, and costs around half of what a central vacuum system cost.

Types

- Wet Dry Vacuums

- Air Operated Vacuums

- Hepa Vacuums

- Continuous Duty Vacuums

- Combustible Dust Vacuums

- Central Vacuum Systems

- Industrial Vacuum Cleaners for Textile

- Liquid Recovery Vacuums

- Flamable Liquid Recovery

- Metalworking Shop Vacuums

- Pharmaceutical Vacuums

- Trim Recovery Vacuums

- Intercept Hoppers and Pre-Separators

- Hose and Tools

Video