Low Pressure Safety Valves

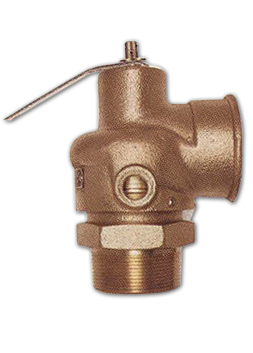

Low Pressure Safety Valve is an automatic system that relieves static pressure on a gas. Used when the difference between the vessel pressure and the ambient atmospheric pressureis small.

The main purpose of the safety valve is to prevent the pressure in the systems to exceed certification pressure. Above certification pressure, no one can guaranty the systems safety - and especially for a steam system with very hot gas with huge amount of latent heat, the consequences can be dramatically.The size of the safety valve depends primarily on the maximum boiler output and the operation pressure of the system. The safety valve shall as minimum have the evacuation capacity of all the vapor the boiler can produce running at full power at the working (or certification) pressure.

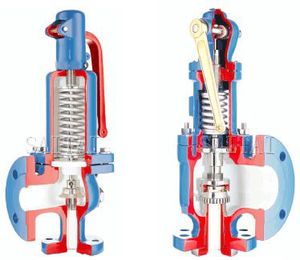

A safety valve is a valve mechanism for the automatic release of a gas from a boiler, pressure vessel, or other system when the pressure or temperature exceeds preset limits. It is part of a bigger set named Pressure Safety Valves (PSV) or Pressure Relief Valves (PRV). The other parts of the set are named Relief Valves,Safety Relief Valves, pilot-operated safety relief valves, low pressure safety valves, vacuum pressure safety valves.

Safety valves were first used on steam boilers during the industrial revolution. Early boilers without them were prone to accidental explosion.