Difference between revisions of "Magnetic Separators"

| Line 1: | Line 1: | ||

[[Category:Magnetic Separating]]{{Knoppen}} | [[Category:Magnetic Separating]]{{Knoppen}} | ||

<noinclude><!------------------------------------------------ | <noinclude><!------------------------------------------------ | ||

| Line 22: | Line 21: | ||

*Pallet Recycling | *Pallet Recycling | ||

*Tire Recycling | *Tire Recycling | ||

In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as at the Shepherd and Murphy mine in Moina, Tasmania, magnetic separation was used to separate the ores. At these mines a device called a Wetherill's Magnetic Separator (invented by John Price Wetherill, 1844–1906) was used. In this machine the raw ore, after calcination was fed onto a moving belt which passed underneath two pairs of electromagnets under which further belts ran at right angles to the feed belt. The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. The second pair were strongly magnetised and attracted the wolframite, which is weakly magnetic. These machines were capable of treating 10 tons of ore a day. | In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as at the Shepherd and Murphy mine in Moina, Tasmania, magnetic separation was used to separate the ores. At these mines a device called a Wetherill's Magnetic Separator (invented by John Price Wetherill, 1844–1906) was used. In this machine the raw ore, after calcination was fed onto a moving belt which passed underneath two pairs of electromagnets under which further belts ran at right angles to the feed belt. The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. The second pair were strongly magnetised and attracted the wolframite, which is weakly magnetic. These machines were capable of treating 10 tons of ore a day. | ||

Latest revision as of 00:41, 14 January 2013

Machines used for Magnetic separation. This is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet. Magnetic separation is one of the most reliable ways to remove unwanted ferrous metals during the processing of raw materials. From recycling plants to food and pharmaceutical manufacturing, we have the perfect industrial magnet to assist your operation.

Industry

- Aggregate & Mining

- Food Processing

- Textile Industries

- Pharmaceutical and Chemical Industries

- Wood Processing

- Pallet Recycling

- Tire Recycling

In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as at the Shepherd and Murphy mine in Moina, Tasmania, magnetic separation was used to separate the ores. At these mines a device called a Wetherill's Magnetic Separator (invented by John Price Wetherill, 1844–1906) was used. In this machine the raw ore, after calcination was fed onto a moving belt which passed underneath two pairs of electromagnets under which further belts ran at right angles to the feed belt. The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. The second pair were strongly magnetised and attracted the wolframite, which is weakly magnetic. These machines were capable of treating 10 tons of ore a day.

Working Principle

All materials possess magnetic properties. Substances that have a greater permeability than air are classified as paramagnetic; those with a lower permeability are called diamagnetic. Paramagnetic materials are attracted to a magnet; diamagnetic substances are repelled. Very strongly paramagnetic materials can be separated from weakly or nonmagnetic materials by the use of low-intensity magnetic separators. Minerals such as hematite, limonite, and garnet are weakly magnetic and can be separated from nonmagnetics by the use of high-intensity separators.

Magnetic separation method is based on the difference of mineral magnetic, bearing different forces in the magnetic field of magnetic separator, resulting in material separation. It is mainly used for sorting ferrous metal ores (iron, manganese, chromium); as well as non-ferrous and rare metals. With good separation efficiency, high processing capacity, and high recovery rate, the application of magnetic separation method in the new iron ore dressing plant is very common. The working principle of magnetic separation is that materials which is going to be elected bearing the force of magnetic and other mechanical (such as gravity, centrifugal force, friction, medium resistance, etc.) together, in the sorting space of the magnetic separator. The magnetic suffered by mineral grains is related with the size and magnetic of the mineral; non-magnetic mineral particles mainly by mechanical force. Consequently, magnetic mineral particles and non-magnetic mineral particles move along different paths to get separation. In general the magnetic force bore by magnetic particles is proportional to the strength and gradient of the magnetic field.

There is a magnetic field around the magnetic materials. Magnetic field can be divided into uniform magnetic field and non-uniform magnetic field. The strength and direction of various points in uniform magnetic field are in the same size; and the strength and direction in non-uniform magnetic field are always changing. Mineral particles in a uniform magnetic field only by the role of the torque, its long axis parallel to the direction of magnetic field; in the non-uniform magnetic field, the mineral particles not only by the role of the torque, but also by the magnetic force, resulting in mineral particles both rotation and moving to the direction of magnetic field gradient increasing, and being sucked in the magnet surface in the last. Such mineral particles with different magnetic can be separation. Therefore, the magnetic selection is a method based on the differences of permeability between minerals to achieve separation in the non-uniform magnetic field.

Types

- Magnetic Chutes

- Magnetic Clarifiers

- Magnetic Cyclones

- Magnetic Decanters

- Magnetic Dedusters

- Magnetic Deferrizers

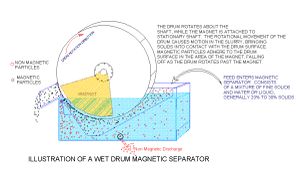

- Magnetic Drums

- Magnetic Elutriators

- Magnetic Extractors

- Magnetic Flotation Cells

- Magnetic Grates

- Magnetic Gravity Separators

- Magnetic Grids

- Magnetic Humps

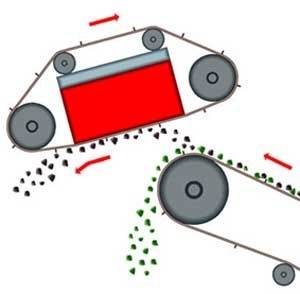

- Magnetic Pulleys

- Magnetic Rods

- Magnetic Sieve Shakers

- Magnetic Sieves

- Magnetic Strainers

- Magnetic Thickeners

- Magnetic Tramp Metal Removers

Video