Mechanically Fluidized Plough Mixers

Mechanically Fluidized Plough Mixers provide quick, intense mixing without the application of high shear. Mechanical fluidization is the process of separation and agitation of the particles using impingement of the material mixing elements mounted on a rotating shaft located within a cylindrical horizontal vessel. The plough shaped mixing elements are designed to lift and separate the product within the vessel.

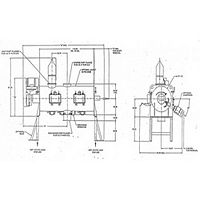

Design Construction and Operation

The Mechanically Fluidized Plough Mixer consists of a cylindrical drum containing plough shaped in the centre of the drum and has welded bolted arms on which the plough shaped mixing elements are mounted. The ploughshare mixer gets is name because of these plough shaped mixing elements. Independently driven high speed choppers may be installed to dispense. Agglomerators and control granulators during the mixing process.

The shaft is powered by a drive system comprising of a motor gearbox and couplings. The shaft exits the mixer drum at either ‘end through the end plates bolted or welded to the cylindrical shell. The area where the shaft exits container is provided with a seating arrangement to ensure that material does not travel from the container to the outside and vice versa. The mixer assembly along with the drive system components Viz motor, gearbox coupling and bearings supports is mounted on a supporting frame.

Common Features

- Thorough dispersion of minor ingredients

- Controllable dispersion of liquids

- Improved temperature control

- Homogenous mix regardless of differences in raw material densities and/or particle size

Video