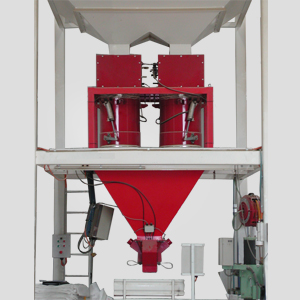

Net Weighers

Jump to navigation

Jump to search

Net Weighers are bulk weighing machines that weighs the product in a vessel above the bag. Gross weight is a term that generally is found in commerce or trade applications, and refers to the total weight of a product and its packaging.

Compared to Gross Weighers

- Very fast. The next weighing cycle can start as soon as the weigher doors have closed, whilst the currently filled bag is being dropped and a fresh one fitted into the clamps. Nett weighers will operate at 10 cycles per minute minimum for most materials, and 15 cycles per minute with excellent accuracy can be achieved with certain materials and bag weights.

- Very accurate. The inflight amount of material is smaller than a gross weigher, due to a shorter distance between the feeder outlet and the weigh hopper. The weigher is always a constant distance from the feeder outlet, ensuring repeatability. There is also virtually no opportunity for the operator to tamper with the weigher parts during filling.

- Large headroom required. For most nett weighing systems, at least 5 or 6 metres headroom is required, which would include a 1000 Litre surge hopper at the top.

- More expensive. A weigh hopper and more ancillaries / metal parts are required compared to a gross weigher, which increases cost.