Difference between revisions of "Non-Return Valves"

| Line 1: | Line 1: | ||

[[Category:Valves]]{{Knoppen}} | [[Category:Valves]]{{Knoppen}} | ||

[[File:Non return valves.jpg|thumb|right|Non-Return Valves]] | |||

[[File:Non return valve graph.jpg|thumb|right|Graph of non-return valve]] | |||

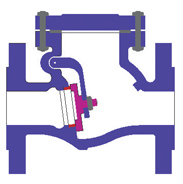

'''Non-Return Valves''',[[Check Valves]], clack valve, or one-way valves are mechanical devices, [[Valves]], which normally allows fluid to flow through it in only one direction. | |||

Non-return valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of non-return valves used in a wide variety of applications. Non-return valves are often part of common household items. Although they are available in a wide range of sizes and costs, non-return valves generally are very small, simple, and/or inexpensive. Non-return valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies of most non-return valvesare made of plastic or metal. | |||

An important concept in non-return valves is the cracking pressure which is the minimum upstream pressure at which the valve will operate. Typically the non-return valve is designed for and can therefore be specified for a specific cracking pressure. | |||

Heart valves are essentially inlet and outlet non-return valve for the heart ventricles, since the ventricles act as pumps.Non-return valves protect plants, pipelines and outlet points against reverse gasflow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes and flow rates . | |||

non return | |||

The sophisticated valve technology of non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages and dirt filters at the inlet point assure long service life of the non-return valves.Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases. | |||

Latest revision as of 00:17, 16 January 2013

Non-Return Valves,Check Valves, clack valve, or one-way valves are mechanical devices, Valves, which normally allows fluid to flow through it in only one direction.

Non-return valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of non-return valves used in a wide variety of applications. Non-return valves are often part of common household items. Although they are available in a wide range of sizes and costs, non-return valves generally are very small, simple, and/or inexpensive. Non-return valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies of most non-return valvesare made of plastic or metal.

An important concept in non-return valves is the cracking pressure which is the minimum upstream pressure at which the valve will operate. Typically the non-return valve is designed for and can therefore be specified for a specific cracking pressure. Heart valves are essentially inlet and outlet non-return valve for the heart ventricles, since the ventricles act as pumps.Non-return valves protect plants, pipelines and outlet points against reverse gasflow and meet all relevant standards and regulations. The product range of non-return valves includes a large choice of nominal sizes and flow rates .

The sophisticated valve technology of non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages and dirt filters at the inlet point assure long service life of the non-return valves.Some non-return valve models can also be used as flashback arrestors. All non-return valves can be mounted in any orientation, are available with all connections, in brass and stainless steel and are suitable for almost all technical gases.