Difference between revisions of "PLC Controllers"

(Created page with "Category:Control Systems{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * ...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

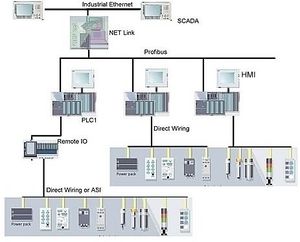

[[File:PLC.png|thumb|right|PLC Controllers]] | |||

[[File:PLC control.jpg|thumb|right|PLC Controllers]] | |||

'''Programmable Logic Controller(PLC)''' or Programmable Controller is a digital computer used for automation of electro mechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many industries and machines. Unlike general-purpose computers, the PLC is designed for multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or | |||

non-volatile memory. A PLC is an example of a hard real time system since output results must be produced in response to input conditions within a limited time, otherwise unintended operation will result.Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential or position control, timed counting and input or output control are widely applied to the field of industrial automation control. | |||

Latest revision as of 07:16, 9 December 2012

Programmable Logic Controller(PLC) or Programmable Controller is a digital computer used for automation of electro mechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many industries and machines. Unlike general-purpose computers, the PLC is designed for multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory. A PLC is an example of a hard real time system since output results must be produced in response to input conditions within a limited time, otherwise unintended operation will result.Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential or position control, timed counting and input or output control are widely applied to the field of industrial automation control.