Difference between revisions of "Plate Coolers"

Jump to navigation

Jump to search

| Line 12: | Line 12: | ||

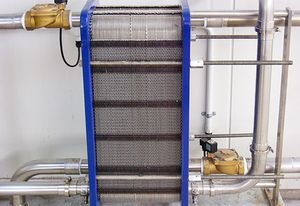

A | A '''Plate Coolers''' are simple [[Heat Exchangers ]]that captures the heat of warm milk and transfers it to the cold incoming water. | ||

In dairy farm’s milk cooling is a significant percentage of electricity costs.Milk leaves a cow’s body at 98 degrees Fahrenheit and needs to be cooled quickly to less than 40 degrees. An in-line plate cooler lowers the milk’s temperature before milk enters the bulk tank to be cooled further. Plate coolers cool milk quickly, which helps lower bacteria counts and is easier on compressors. An in-line cooler is one of the best energy investments in a dairy operation. | In dairy farm’s milk cooling is a significant percentage of electricity costs.Milk leaves a cow’s body at 98 degrees Fahrenheit and needs to be cooled quickly to less than 40 degrees. An in-line plate cooler lowers the milk’s temperature before milk enters the bulk tank to be cooled further. Plate coolers cool milk quickly, which helps lower bacteria counts and is easier on compressors. An in-line cooler is one of the best energy investments in a dairy operation. | ||

==Benefits== | |||

* the milk is pre-cooled - by the time is reaches the refrigerated storage tank. | |||

* water that needs heating for varied uses is pre-warmed. | |||

Latest revision as of 07:22, 4 August 2012

A Plate Coolers are simple Heat Exchangers that captures the heat of warm milk and transfers it to the cold incoming water.

In dairy farm’s milk cooling is a significant percentage of electricity costs.Milk leaves a cow’s body at 98 degrees Fahrenheit and needs to be cooled quickly to less than 40 degrees. An in-line plate cooler lowers the milk’s temperature before milk enters the bulk tank to be cooled further. Plate coolers cool milk quickly, which helps lower bacteria counts and is easier on compressors. An in-line cooler is one of the best energy investments in a dairy operation.

Benefits

- the milk is pre-cooled - by the time is reaches the refrigerated storage tank.

- water that needs heating for varied uses is pre-warmed.