Difference between revisions of "Pocket Belt Conveyors"

Jump to navigation

Jump to search

m |

|||

| Line 1: | Line 1: | ||

[[Category:Belt Conveying]]{{Knoppen}} | [[Category:Belt Conveying]]{{Knoppen}} | ||

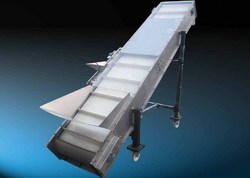

[[File:Pocket-belt-conveyor.jpg|thumb|right|Pocket Belt Conveyors]] | [[File:Pocket-belt-conveyor.jpg|thumb|right|Pocket Belt Conveyors]] | ||

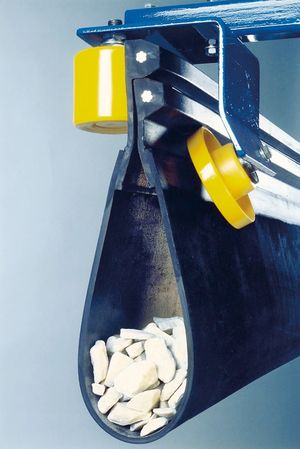

[[File:Pocket-conveyor-belt.jpg|thumb|right|Pocket Belt Conveyors]] | [[File:Pocket-conveyor-belt.jpg|thumb|right|Pocket Belt Conveyors]] | ||

'''Pocket Belt Conveyors''' have been shown to be not only extremely curve-negotiable and economical but, at the same time, ultra-eco-friendly in operation. The pouch-shaped belt provides a unique solution for transport of bulk materials. It remains closed from the feeding point to the discharge point. This enables it to negotiate small-radius bends, thereby rendering transfer stations superfluous. The fact that the belt is also closed on the return run completely eliminates dust pollution and soiling of the conveyor system due to spillage. The [[Conveyor Belts ]] remains complete protected and any negative impact on the environment is avoided. A further advantage is that the belt cleans itself. | |||

==Advantages== | ==Advantages== | ||

* Copes very well with height differences in tight situations | * Copes very well with height differences in tight situations | ||

* Negotiates curves very well, rendering transfer points largely superfluous | * Negotiates curves very well, rendering transfer points largely superfluous | ||

* Prevents spillage | * Prevents spillage | ||

* Makes possible two-way conveyor system | * Makes possible two-way conveyor system | ||

* Prevents pollution due to dust emissions | * Prevents pollution due to dust emissions | ||

* Protects sensitive materials | * Protects sensitive materials | ||

* Allows for easy mounting | * Allows for easy mounting | ||

* Make minimal space demands | * Make minimal space demands | ||

* Allows for gradients of up to 35°Cleans itself | * Allows for gradients of up to 35°Cleans itself | ||

* Can cope with 180° curves with a radius less than 1 meter | * Can cope with 180° curves with a radius less than 1 meter | ||

* Opens the way to many feed and discharge options | * Opens the way to many feed and discharge options | ||

Latest revision as of 06:26, 12 November 2013

Pocket Belt Conveyors have been shown to be not only extremely curve-negotiable and economical but, at the same time, ultra-eco-friendly in operation. The pouch-shaped belt provides a unique solution for transport of bulk materials. It remains closed from the feeding point to the discharge point. This enables it to negotiate small-radius bends, thereby rendering transfer stations superfluous. The fact that the belt is also closed on the return run completely eliminates dust pollution and soiling of the conveyor system due to spillage. The Conveyor Belts remains complete protected and any negative impact on the environment is avoided. A further advantage is that the belt cleans itself.

Advantages

- Copes very well with height differences in tight situations

- Negotiates curves very well, rendering transfer points largely superfluous

- Prevents spillage

- Makes possible two-way conveyor system

- Prevents pollution due to dust emissions

- Protects sensitive materials

- Allows for easy mounting

- Make minimal space demands

- Allows for gradients of up to 35°Cleans itself

- Can cope with 180° curves with a radius less than 1 meter

- Opens the way to many feed and discharge options