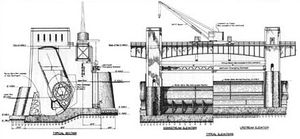

Roller Gates

Roller Gates are designed to control flow through large waterway openings where economy and ease of operation are important. They may be designed as either upward or downward opening. A roller or fixed wheel gate consists of a fabricated steel slide with cast iron rollers and rubber seals. The gate leaf is a box-like design of welded construction. It varies in width and height as required by the size of the opening in the concrete and varies in thickness depending on the depth of water. Recesses at the sides of the gate opening are provided with rails and with contact faces for side seals. The thrust developed from water pressure against the gate is transmitted through the rollers to the rails and into the structure. The lift capacity required to open the gate under maximum operating conditions is minimized as the thrust caused by the water pressure is transferred to rolling friction .

Types of Roller Gates

There are two types of roller gates: the overflow type for use where the water depth is the same as the height of the gate slide; and the breastwall type where water is considerably deeper than the height of the gate and/or where complete closure of the opening is required.

Overflow Type

The overflow type normally is designed for 1-ft water depth over the top of the gate. Typical installations are on the top of a dam to increase water storage, in the spillway of a dam to add water storage, and in diversion ditches or streams through levees on flood control projects. In recent years this type of gate has found wide application for control of power plant cooling water systems and for pump and turbine isolation gates.

Breastwall Type

The breastwall type is designed for the maximum heads that will be encountered on the horizontal centerline of the gate. These heads range up to 40 ft or more. The breastwall-type gate functions in connection with a wall over the top of the opening and usually is used for flood control on a storm sewer or any other conduit that flows under a levee. This gate is similar in construction to the overflow type, but the higher head of water requires the gate to be strengthened with additional or heavier cross-support members and with larger rollers. Also, a top seal makes contact with an angle embedded in the concrete across the top of the opening. This angle must project from the face of the concrete, thus permitting the top seal to move upward without the bulb of the seal being dragged against the concrete and above the opening.

Operation

Roller gates are usually operated with threaded stems and manual or electric lifts. Single stems are used when the gate width does not exceed twice the height. Gates that are very wide compared to their height should have tandem stems. Very tall gates may be equipped with tandem stems and traveling stem guides in order to keep the stem size, yoke and lift in an optimum cost range. Roller gates may also be cylinder operated; however, very tall or very wide gates requiring tandem cylinders are not recommended due to synchronization or alignment problems. Another way of operating gates is with a rope hoist . Close attention must be paid to closing friction loads since the gate may require a ballast to close against the operating head. A roller gate may also serve as a removable bulkhead using an overhead crane. Lifts may be mounted on the concrete structure and are available with pedestals or wall brackets. More commonly, there is no concrete structure above the gate opening. In this case, the lift or tandem lifts are mounted on a head frame which can be either attached to the structure or be attached to the extended slot assemblies .

Applications

- Power plant cooling water systems

- Municipal waterworks

- Flood control projects

- Municipal sewage treatment plants

- Industrial water control projects

- Irrigation systems

- On top of dams to increase reservoir capacity