SCADA Systems

SCADA System (supervisory control and data acquisition) is a type of industrial control system (ICS). Industrial control systems are computer controlled systems that monitor and control industrial processes that exist in the physical world. SCADA systems historically distinguish themselves from other ICS systems by being large scale processes that can include multiple sites, and large distances.

These processes include industrial, infrastructure, and facility-based processes, as described below:

- Industrial processes include those of manufacturing, production, power generation, fabrication, and refining, and may run in continuous, batch, repetitive, or discrete modes.

- Infrastructure processes may be public or private, and include water treatment and distribution, waste water collection and treatment, oil and gas pipelines, electrical power transmission anddistribution, wind farms, civil defense siren systems, and large communication systems.

- Facility processes occur both in public facilities and private ones, including buildings, airports, ships, and space stations. They monitor and control heating, ventilation, and air conditioning systems (HVAC), access, and energy consumption.

Common system components

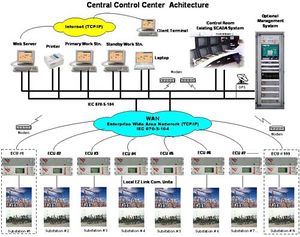

A SCADA system usually consists of the following subsystems:

- A human–machine interface or HMI is the apparatus or device which presents process data to a human operator, and through this, the human operator monitors and controls the process.

- SCADA is used as a safety tool as in lock-out tag-out

- A supervisory (computer) system, gathering (acquiring) data on the process and sending commands (control) to the process.

- Remote terminal units (RTUs) connecting to sensors in the process, converting sensor signals to digital data and sending digital data to the supervisory system.

- Programmable Logic controller or PLC Controllers used as field devices because they are more economical, versatile, flexible, and configurable than special-purpose RTUs.

- Communication infrastructure connecting the supervisory system to the remote terminal units.

- Various process and analytical instrumentation

How SCADA Works

The measurement and control system of SCADA has one master terminal unit (MTU) which could be called the brain of the system and one or more remote terminal units (RTU). The RTUs gather the data locally and send them to the MTU which then issues suitable commands to be executed on site. A system of either standard or customized software is used to collate, interpret and manage the data. SCADA as of now uses predominantly open-loop control systems, though some closed-loop characteristics are often built in. As this is an open-loop system, it means that SCADA system cannot use feedback to check what results its inputs have produced. In other words, there is no machine-learning.