Difference between revisions of "Sandwich Belt Conveyors"

(Created page with "Category:Belt Conveying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Im...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

This | [[File:Sandwich-belt-conveyor.jpg|thumb|right|Sandwich Belt Conveyors]] | ||

[[File:Sandwich-belt-conveyor1.jpg|thumb|right|Sandwich Belt Conveyors]] | |||

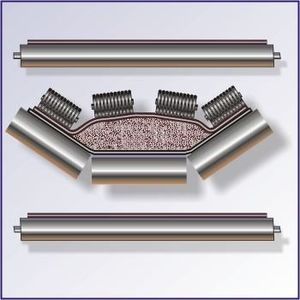

'''Sandwich Belt Conveyor''' uses two conveyor belts, face-to-face, to gently but firmly contain the product being carried, hence making steep incline and even vertical-lift runs easily achievable.Sandwich belt conveyors are so named due to the manner in which the material is sandwiched between two rubber belts before it is inclined at angles up to 90 degrees.Material is hugged by the belts throughout the inclined section to ensure that it does not slide back down the incline, even if the conveyor trips. This hugging pressure is achieved by either the belt tension or by means of pressing assemblies which force the belts together. | |||

A fundamental requirement of any proposed application of sandwich belt conveyors is that the material to be transported must have a reasonable internal friction angle.Sandwich belt conveyors offer the potential to load material at a considerable rate at one level and to elevate the product to a second level via an inclined section which could be angled at up to 90 degrees to horizontal. | |||

Latest revision as of 09:05, 21 August 2012

Sandwich Belt Conveyor uses two conveyor belts, face-to-face, to gently but firmly contain the product being carried, hence making steep incline and even vertical-lift runs easily achievable.Sandwich belt conveyors are so named due to the manner in which the material is sandwiched between two rubber belts before it is inclined at angles up to 90 degrees.Material is hugged by the belts throughout the inclined section to ensure that it does not slide back down the incline, even if the conveyor trips. This hugging pressure is achieved by either the belt tension or by means of pressing assemblies which force the belts together.

A fundamental requirement of any proposed application of sandwich belt conveyors is that the material to be transported must have a reasonable internal friction angle.Sandwich belt conveyors offer the potential to load material at a considerable rate at one level and to elevate the product to a second level via an inclined section which could be angled at up to 90 degrees to horizontal.