Screw Valves

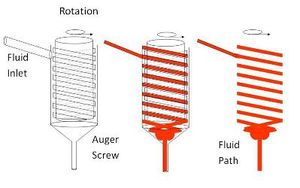

Screw Valve utilizes a screw or an auger to turn fluid down a cylinder. The rotation of the screw creates a shearing force on the fluid which forces the fluid down the threads of the screw. This technology has been around since the Egyptian times where the technology was used to move water from the Nile River.Screw valve is like a drill. Drills cut into solids and moves the saw dust out the groves. An screw valve is fixed and moves the fluid through the threads.

How do screw valves work

Air pressure on a syringe forces fluids down a tube and into the valve. The fluid hits the screw. The screw is turning and drives the fluid down along the threads. This turning, or rotation, is driven from the motor above. The motor is controlled in a couple of ways: It can be turned on for a set amount of time or a set rotation .

The rotation of the screw creates a shear force on the fluid which forces the fluid to move down the screw. The speed and how much rotation control the amount of fluid going through.As the fluid reaches the bottom of the screw, the flow dynamics change. It takes some force to get the fluid to flow through the needle and the hub right before the needle starts. This is a resistance to flow. The screw will continue to turn creating a needle pressure which is high enough to force fluid through the needle. Narrow, long needles have a lot of resistance and short, big needles have much less. This restriction creates back flow. The screw is pushing fluid into the hub and needle, faster than the fluid can move through the needle, so it starts to flow back up the sides toward the syringe. This back flow is proportional to the pressure drop from the needle hub to the syringe. The flow out the needle is equal to the valve shear flow minus the back flow. If the needle requires a higher pressure to flow than the screw can deliver then back pressure is created. The back pressure is the pressure necessary to create a flow of fluid between the screw and the screw housing. The back pressure created by the turning of fluid by the screw is equal to the pressure relieved through the needle minus the pressure of the fluid created by the screw. It other words there are a couple of huge differences between positive displacement valves and screw valves: One, the needle configuration that is how big the opening is and how long it is dramatically affect how much fluid comes out. And two if the pressure is too much, the fluid churns in the valve and gets beaten up this can cause real problems depending on the fluid like curing glue, or coining and cold welding solder balls, and wearing out the screw and sleeve the cylindrical hole around the screw. Cavitation can also happen if the motor over powers the fluid and creates a small void