Difference between revisions of "Secondary Belt Cleaners"

Jump to navigation

Jump to search

(Created page with "Category:Cleaning{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| Line 1: | Line 1: | ||

[[Category:Cleaning]]{{Knoppen}} | [[Category:Cleaning]]{{Knoppen}} | ||

[[File:Secondary_Belt_Cleaners_01.jpg|thumb|right|Secondary Belt Cleaners]] | |||

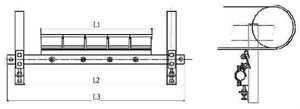

* | [[File:Secondary_Belt_Cleaners_02.jpg|thumb|right|Secondary Belt Cleaners Outline]] | ||

* | '''Secondary belt cleaners''' are designed to be installed immediately after the head pulley to remove fine carry back adhering to the belt. Secondary belt cleaners are generally set up behind the tangent point where the belt leaves the pulley and are responsible for final belt cleaning. Secondary Belt Cleaners are installed after the point where the belt leaves the head (discharge) pulley and or anywhere on the return side of the belt where it can be cleaned and maintained effectively. | ||

* | |||

* | |||

* | ==General Features== | ||

* | *Blade materials: Tungsten carbide, stainless steel or acid proof steel | ||

*Tensioning handled by special torsion spring tensioning device | |||

*Spring steel structure keeps the material from adhering to the belt cleaner and reduces maintaining | |||

*Adjusting of the blade pressure together with flexible rubber cushion secure the right blade position against the belt | |||

*Linear touch enables small blade pressure, which saves the belt and gives a good cleaning result | |||

*Operating area is of very abrasive materials | |||

==Video== | |||

<youtube>_7hQWhyIOqc</youtube> | |||

Latest revision as of 07:11, 11 June 2013

Secondary belt cleaners are designed to be installed immediately after the head pulley to remove fine carry back adhering to the belt. Secondary belt cleaners are generally set up behind the tangent point where the belt leaves the pulley and are responsible for final belt cleaning. Secondary Belt Cleaners are installed after the point where the belt leaves the head (discharge) pulley and or anywhere on the return side of the belt where it can be cleaned and maintained effectively.

General Features

- Blade materials: Tungsten carbide, stainless steel or acid proof steel

- Tensioning handled by special torsion spring tensioning device

- Spring steel structure keeps the material from adhering to the belt cleaner and reduces maintaining

- Adjusting of the blade pressure together with flexible rubber cushion secure the right blade position against the belt

- Linear touch enables small blade pressure, which saves the belt and gives a good cleaning result

- Operating area is of very abrasive materials

Video