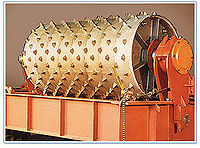

Single Roller Crushers

Single Roller Crushers are designed to last and are suited for primary, heavy-impact applications. They can take on rugged feed such as refuse and 100% rock, but may also be used for more friable materials, such as clean coal and salt, or wet, sticky materials, such as clay and bauxite.

Single Roll Crushers use impact forces created by the rotation of a roll equipped with teeth against a stationary grooved crushing plate to reduce the size of the feed.

Design

- Base frames made with heavy-duty fabricated steel construction

- Hoppers reinforced with renewable, abrasion-resistant steel wear liners

- Crushing plates designed with easy-to-replace, renewable crushing plate tips

- Automatic toggle mechanism allows the crushing plate to hinge open, pass uncrushable tramp material and return to the previous position for continued operation

Operation

The single roll crusher reduces the feeding material in a wedge-shaped crushing area by means of pressure and shearing stress. The crushing body is formed by a rotating roll and an adjustable and spring-mounted crushing plate located on the oppo- site side. The distance between the base of the crushing plate and the tips of the roll crushers teeth forms the adjustable gap width, which can be varied depending on the required final grain size. Any wear and tear which may occur can be ad- justed via the crushing plate. Depending on the feeding material and the required final grain, the roll crusher is equipped with either teeth or ledges. The crushing plate is equipped with a replaceable comb plate.

Advantages

- high and constant capacity

- low susceptibility to breakdowns

- long lifetime

- easy replacement of wear and spare parts

- wide range of application

- high crushing grade

- with a minimum of fine grains

Video