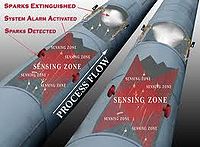

Spark Detection Systems

Spark Detection Systems are primarily used as a fire prevention method in dust collectors and pneumatic conveying systems by detecting and extinguishing sparks and embers. When working materials, sparks are created very quickly. A dull tool, a damaged fan bearing, an over heated motor, or a foreign object within the material can be the cause. This is a constant danger for all facilities where combustible materials are being worked, exhausted, transported, filtered or dried. The damage statistics provided by insurance companies point out that filters, dust collection bins, silos and even complete production lines are the areas at greatest risk. Foreign objects in the conveyed material, defective parts of production machinery, friction processes as well as electric sparks are all identified as fire generating.

Common Benefits

Spark Detection and Extinguishing systems reduce the risk of personnel injuries, equipment damage and loss of production from fires and dust explosions.

In any type of production facility, fire control encompasses a wide range of equipment or systems from building sprinklers to plant site fire departments. A spark detection & extinguishing system must be thought of as part of a plant’s overall security and safety network. Just as a residential alarm system provides protection to a homeowner, a spark detection system provides preventive protection against potential loss of human life, production facilities, equipment and costly downtime.

Common Processes Involved

- Oxidant Concentration Reduction

- Deflagration venting

- Deflagration pressure containment

- Deflagration suppression

- Dilution with non-combustible dust

- Deflagration venting through a dust retention and flame-arresting device

Video