Difference between revisions of "Spin Flash Dryers"

(Created page with "Category:Drying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| Line 5: | Line 5: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

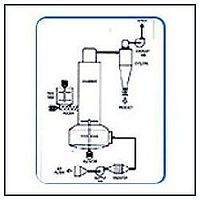

[[File:Spin-flash-dryers-250x250.jpg|thumb|right|200px|Spin Flash Dryer]] | |||

If the wet cake is a paste or sludge, the '''Spin Flash Dryers''' are the most suited for drying application. The dryer is fitted with a mechanical agitator which helps to disperse the wet cake without any need for back mixing of the dry powder. the feeding system includes a feed tank with agitator and a screw feeder for feeding into the drying unit. The heart of drying process is cylindrical drying chamber, where the drying air enters the air distributor. The tangential air distributor of special design introduces the air as an intense swirl flow. the simple spin flash dryer is designed to handle materials that can be suspended directly in air. The drying process usually is completed in 0. 5 - 2 sees, and the final moisture is generally in the constant rate drying zone. Various types of spin flash dryers designs are available based on uniform / non uniform particle size of the feed / product. the feeding of cake is through specially designed paddle mixer / screw conveyor with / without rotary injector depending on rheology of feed material. For difficult to handle feed materials part of dried powder can be re-cycled. Spin flash dryers are suited for filter cakes, semi dried powders. | |||

Revision as of 08:06, 24 July 2012

If the wet cake is a paste or sludge, the Spin Flash Dryers are the most suited for drying application. The dryer is fitted with a mechanical agitator which helps to disperse the wet cake without any need for back mixing of the dry powder. the feeding system includes a feed tank with agitator and a screw feeder for feeding into the drying unit. The heart of drying process is cylindrical drying chamber, where the drying air enters the air distributor. The tangential air distributor of special design introduces the air as an intense swirl flow. the simple spin flash dryer is designed to handle materials that can be suspended directly in air. The drying process usually is completed in 0. 5 - 2 sees, and the final moisture is generally in the constant rate drying zone. Various types of spin flash dryers designs are available based on uniform / non uniform particle size of the feed / product. the feeding of cake is through specially designed paddle mixer / screw conveyor with / without rotary injector depending on rheology of feed material. For difficult to handle feed materials part of dried powder can be re-cycled. Spin flash dryers are suited for filter cakes, semi dried powders.