Difference between revisions of "Tube Chain Mixers"

Jump to navigation

Jump to search

(Created page with "Category:Mixing{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improper u...") |

PurplePen19 (talk | contribs) |

||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Tube Chain Mixers.jpg|thumb|200px|right|Tube Chain Mixers]] | |||

'''Tube Chain Mixers''' are designed for continuous mixing of products. | |||

==Common Features== | |||

*The tubular chain mixer provides continuous mixing of product and comprises of a rotary drum, bearings, and a drive. | |||

*Different products are discharged at the inlets, and metering screw feeders are used to transport the product via a tubular chain conveyor to a drum. | |||

*The drum is equipped with paddles to ensure the product is throughly mixed before it is slowly transported towards the exit end of the tubular conveyor. | |||

*The outlet is located at the end of the tubular conveyor. | |||

*The system is totally enclosed and dust-free. | |||

*Continuous mixing eliminates downtime for loading and unloading of product, thereby increasing productivity. | |||

==Related Video== | |||

<youtube>PxFj7h6Rc9Y</youtube> | |||

Latest revision as of 01:38, 3 September 2012

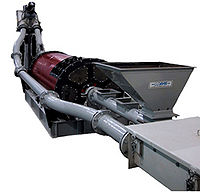

Tube Chain Mixers are designed for continuous mixing of products.

Common Features

- The tubular chain mixer provides continuous mixing of product and comprises of a rotary drum, bearings, and a drive.

- Different products are discharged at the inlets, and metering screw feeders are used to transport the product via a tubular chain conveyor to a drum.

- The drum is equipped with paddles to ensure the product is throughly mixed before it is slowly transported towards the exit end of the tubular conveyor.

- The outlet is located at the end of the tubular conveyor.

- The system is totally enclosed and dust-free.

- Continuous mixing eliminates downtime for loading and unloading of product, thereby increasing productivity.

Related Video