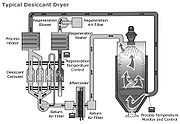

Twin Tower Dryers

The Twin Tower Dryers are used for drying air in storage tanks or pneumatic systems and are beneficial in the drying of hygroscopic (water-absorbing) resins. These dryers remove water from the air by passing it through a desiccant that absorbs moisture.

Features

The Twin Tower Dryers consist mainly of two cylinders containing desiccant, connected by a valve system.

Operation

When the desiccant in the first cylinder is saturated, the air flow can be switched to the cylinder containing the dried desiccant.

Dessicant Types

Common desiccants are silica gel (an oxide of silica), alumina (aluminum oxide) and calcium sulfate (the anhydrous form of gypsum).

Types of Dryers

While manual desiccant dryers exist, many dryers are Twin Tower Dryers.

Most Expensive

Heatless Twin Tower Dryers run a portion of dried compressed air through the previously utilized cylinder to extract moisture from its desiccant.

Least Expensive

Heated purge Twin Tower Dryers use less air than the heatless variety in addition to heat, which helps the air carry away more water as it passes through the saturated desiccant.

Best Compromise

Heated blower purge regenerative Twin Tower Dryers use air from outside the dryer that is heated and sent through the water-saturated desiccant for drying.

Classification

There are different types of Twin Tower Dryers. These are:

- Small Heatless Twin Tower Dryer

- Large Heatless Twin Tower Dryer

- Compact Heatless Twin Tower Dryer

- Mini Heatless Twin Tower Dryer