Difference between revisions of "V-Belts"

(Created page with "Category:Mechanical Components{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the conten...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Mechanical Components]]{{Knoppen}} | [[Category:Mechanical Components]]{{Knoppen}} | ||

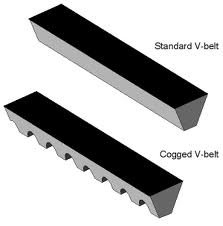

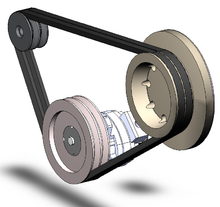

[[File:V-Belts.jpg|thumb|right|V-Belts]] | |||

[[File:V-Belts1.png|thumb|right|V-Belts]] | |||

'''V-Belts''' also known as vee belts or wedge rope solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. The V-belt was developed in 1917 by | |||

John Gates of the Gates Rubber Company. They are generally endless, and their general cross-section shape is trapezoidal. The V shape of the belt tracks in a mating groove in the pulley , with the result that the belt cannot slip off. The belt also tends to wedge into the groove as the load increases the greater the load, the greater the wedging action improving torque transmission and making the V-belt an effective solution, needing less width and tension than flat belts. V-belts trump flat belts with their small center distances and high reduction ratios. The preferred center distance is larger than the largest pulley diameter, but less than three times the sum of both pulleys. Optimal speed range is 1000-7000 ft/min. V-belts need larger pulleys for their larger thickness than flat belts. They can be supplied at various fixed lengths or as a segmented section, where the segments are linked to form a belt of the required length. For high-power requirements, two or more vee belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. The strength of these belts is obtained by reinforcements with fibers like steel, polyester or aramid (e.g.Twaron or Kevlar). This is known as a multiple-V-belt drive or sometimes a classical V-belt drive. When an endless belt does not fit the need, jointed and link V-belts may be employed. However they are weaker and only usable at speeds up to 4000 ft/min. A link v-belt is a number of rubberized fabric links held together by metal fasteners. They are length adjustable by disassembling and removing links when needed. | |||

V-Belt is an endless power-transmission belt with a trapezoidal cross section which runs in a pulley with a V-shaped groove; it transmits higher torque at less width and tension than a flat belt or it is a belt, usually endless, with a trapezoidal cross section which runs in a pulley with a V-shaped groove, with the top surface of the belt approximately flush with the top of the pulley. | |||

Latest revision as of 07:57, 28 January 2013

V-Belts also known as vee belts or wedge rope solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. The V-belt was developed in 1917 by John Gates of the Gates Rubber Company. They are generally endless, and their general cross-section shape is trapezoidal. The V shape of the belt tracks in a mating groove in the pulley , with the result that the belt cannot slip off. The belt also tends to wedge into the groove as the load increases the greater the load, the greater the wedging action improving torque transmission and making the V-belt an effective solution, needing less width and tension than flat belts. V-belts trump flat belts with their small center distances and high reduction ratios. The preferred center distance is larger than the largest pulley diameter, but less than three times the sum of both pulleys. Optimal speed range is 1000-7000 ft/min. V-belts need larger pulleys for their larger thickness than flat belts. They can be supplied at various fixed lengths or as a segmented section, where the segments are linked to form a belt of the required length. For high-power requirements, two or more vee belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. The strength of these belts is obtained by reinforcements with fibers like steel, polyester or aramid (e.g.Twaron or Kevlar). This is known as a multiple-V-belt drive or sometimes a classical V-belt drive. When an endless belt does not fit the need, jointed and link V-belts may be employed. However they are weaker and only usable at speeds up to 4000 ft/min. A link v-belt is a number of rubberized fabric links held together by metal fasteners. They are length adjustable by disassembling and removing links when needed.

V-Belt is an endless power-transmission belt with a trapezoidal cross section which runs in a pulley with a V-shaped groove; it transmits higher torque at less width and tension than a flat belt or it is a belt, usually endless, with a trapezoidal cross section which runs in a pulley with a V-shaped groove, with the top surface of the belt approximately flush with the top of the pulley.