Vertical Conveyors

Vertical Conveyors are Conveyors that is used for low-frequency intermittent vertical transfers. Types of vertical conveyors include Vertical Lift Conveyors and vertical reciprocating conveyors, both of which more closely resemble an industrial lift than a traditional conveyor. A vertical conveyor is an elevator type lift used to move products from one floor to another. It is often referred to as a freight elevator. The main difference between a freight elevator and a vertical conveyor, however, is that the former can travel between several floors while the latter typically only travels between two. There are often a series of vertical conveyor systems used to access several floors when the need arises to do so.

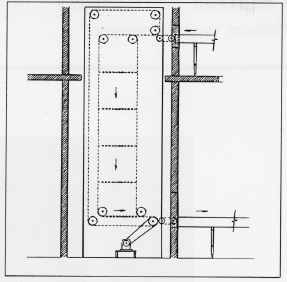

Vertical Conveyors are fully integrated, multiple-position conveyors used to raise or lower products between conveyor elevations. When used in tandem, they can also form a conveyor bridge above heavily congested plant areas. Generally, the vertical conveyor uses a section of slip-torque or slip-trak bed to transfer products in and out of the vertical conveyor shaft. Once the product is inside the shaft, the vertical conveyor mechanism activates and raises or lowers the entire conveyor bed to the appropriate elevation.Vertical conveyors can also be used to accumulate product in the vertical direction.

Advantages and Disadvantages

A vertical conveyor is a machine which can be used to move products automatically from one level to another. In internal logistics, there are various ways for getting product flows up or down. A solution which is often used is the deployment of incline or lowering belts. When placed at an angle in order to bridge a height difference, such belt conveyors also have the advantage of covering a certain distance. A disadvantage is the loss of much useful floor space as a result of the presence of the necessary supports for Belt Conveyors .A bigger distance over a smaller floor area can be bridged using a product lift or a vertical conveyor. A continuous conveyor or a discontinuous conveyor can be chosen as a vertical conveyor. Continuous conveyors can take the form of a spiral conveyor, an L-shaped conveyor or platform lift or a product lift fitted with a fork.