Difference between revisions of "Vertical Lift Modules"

(Created page with "Category:Warehousing{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Impro...") |

PurplePen19 (talk | contribs) |

||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Vertical Lift Modules_1.jpg|thumb|200px|right|Vertical Lift Modules]] | |||

[[File:Vertical Lift Modules_2.jpg|thumb|200px|right|Vertical Lift Modules]] | |||

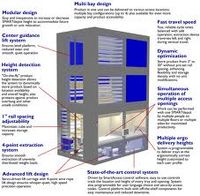

'''Vertical Lift Modules''' are enclosed system of vertically arranged trays, an extraction platform and a series of computerized controls that delivers goods to an ergonomically positioned workstation where an operator picks or replenishes the goods. The VLM automatically locates stored goods and retrieves trays from both the front and back of the unit with a push of a button or a scan of a bar code. | |||

==Common Advantages== | |||

*Save up to 75% of their wasted space | |||

*Increase accuracy to 99.9%+ levels | |||

*Reduce labor by 2/3 | |||

*Improve inventory turns | |||

*Receive 100% ergonomic access to help eliminate operator injuries | |||

==Typical Constructions== | |||

Vertical Lift module is constructed of an industrial steel rack structure with varied payload capacities depending on the manufacturer and the application for use. Each rack frame is composed of front and rear parallel sections for storage, with an extractor (elevator) mechanism aisle in between. The extractor (elevator) mechanism travels vertically in the extractor aisle, between the front and rear storage sections, to retrieve / deposit part trays to their assigned location, or to the delivery / access window. Once the extractor mechanism locates the appropriate tray location or delivery / access window, it extracts or deposits the tray at that location. | |||

==Video== | |||

<youtube>oiZv9-0UC2I</youtube> | |||

Latest revision as of 08:16, 28 September 2012

Vertical Lift Modules are enclosed system of vertically arranged trays, an extraction platform and a series of computerized controls that delivers goods to an ergonomically positioned workstation where an operator picks or replenishes the goods. The VLM automatically locates stored goods and retrieves trays from both the front and back of the unit with a push of a button or a scan of a bar code.

Common Advantages

- Save up to 75% of their wasted space

- Increase accuracy to 99.9%+ levels

- Reduce labor by 2/3

- Improve inventory turns

- Receive 100% ergonomic access to help eliminate operator injuries

Typical Constructions

Vertical Lift module is constructed of an industrial steel rack structure with varied payload capacities depending on the manufacturer and the application for use. Each rack frame is composed of front and rear parallel sections for storage, with an extractor (elevator) mechanism aisle in between. The extractor (elevator) mechanism travels vertically in the extractor aisle, between the front and rear storage sections, to retrieve / deposit part trays to their assigned location, or to the delivery / access window. Once the extractor mechanism locates the appropriate tray location or delivery / access window, it extracts or deposits the tray at that location.

Video