Difference between revisions of "Vertical Shaft Crushers"

Jump to navigation

Jump to search

PurplePen19 (talk | contribs) |

|||

| Line 1: | Line 1: | ||

[[Category:Particle Size Reduction]]{{Knoppen}} | [[Category:Particle Size Reduction]]{{Knoppen}} | ||

[[File:Vertical Shaft Crushers_1.jpg|thumb|200px|right|Vertical Shaft Crushers]] | [[File:Vertical Shaft Crushers_1.jpg|thumb|200px|right|Vertical Shaft Crushers]] | ||

[[File:Vertical Shaft Crushers_2.jpg|thumb|200px|right|Vertical Shaft Crushers Principle]] | [[File:Vertical Shaft Crushers_2.jpg|thumb|200px|right|Vertical Shaft Crushers Principle]] | ||

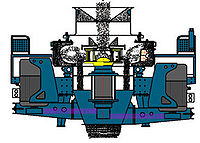

'''Vertical Shaft Crushers''' are [[Impact Crushers]] that are applied widely for the powder process of mineral product including: | |||

'''Vertical Shaft Crushers''' are [[Impact Crushers]] that are applied widely for the powder process of mineral product including | *Metal and non-metal ore | ||

*Fireproof material | |||

*Bauxite | |||

*Diamond dust | |||

*Glass raw materials | |||

*Architectural materials | |||

*Artificial sand | |||

*All kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials. | |||

==Operations== | ==Operations== | ||

The | The material which falls into the high-speed rotating impeller from the upper of the machine, were stroked with other material, which more around the impeller, because of high-speed centrifugal force. After they strike mutually, whirling fluid is produced between the impeller and outer covering. Through repeatedly striking and rubbing, the materials are crushed into pieces and straightly come out of the lower. The operating process circulates repeatedly. And then attains the fineness of the product. | ||

Revision as of 10:05, 31 July 2013

Vertical Shaft Crushers are Impact Crushers that are applied widely for the powder process of mineral product including:

- Metal and non-metal ore

- Fireproof material

- Bauxite

- Diamond dust

- Glass raw materials

- Architectural materials

- Artificial sand

- All kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials.

Operations

The material which falls into the high-speed rotating impeller from the upper of the machine, were stroked with other material, which more around the impeller, because of high-speed centrifugal force. After they strike mutually, whirling fluid is produced between the impeller and outer covering. Through repeatedly striking and rubbing, the materials are crushed into pieces and straightly come out of the lower. The operating process circulates repeatedly. And then attains the fineness of the product.

Typical Features

- Special light oil lubrication system ensures the temperature is below 25℃

- Brand new automatic protection device supplies VSI with vibrating, oil filtering and warning systems

- Hydraulic system allows automatic uncovering, reducing intensity of labor and making maintenance easier

- Optimized arrangement design of wear resistant materials increase the service life of the machine by over 40%, thus decrease the cost by over 40%

- The mainframe is made with rivet hot technique, which enhances intensity of structure and tenacity, and ensures stable performance

Video