Difference between revisions of "Wear Bends"

(Created page with "Category:Piping{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improper u...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Wear Bends.jpg|thumb|right|Wear Bends]] | |||

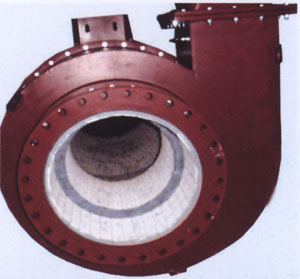

'''Wear Bends''' are used for slurry hand-ling in heavy wear applications in the mining processing industry, coal refinement plants, power plants in the steel and cement industries and other applications where high wear resistance is required. | |||

Wear bends can be manufactured from corrothene or corromide depending on the application. Corrothene is used in most applications where captive wear bends are not likely to be subject to high temperatures and is impervious to moisture which makes it ideally suited to applications in damp and wet conditions, it can be used safely in direct contact with food, it has an extremely low coefficient of friction whilst retaining excellent wear resistant properties. In all, corrothene is the ideal material for captive wear bends in all industries. | |||

Corromide wear bends are suitable for use at more elevated temperatures and where sharp edges such as broken glass or aggregate containing flint are likely to be encountered. Wear bends are usually manufactured from one of the self lubricated grades such as corromide COF (oil impregnated) or corromide CSL (which contains a solid lubricant) | |||

Revision as of 06:56, 2 January 2013

Wear Bends are used for slurry hand-ling in heavy wear applications in the mining processing industry, coal refinement plants, power plants in the steel and cement industries and other applications where high wear resistance is required.

Wear bends can be manufactured from corrothene or corromide depending on the application. Corrothene is used in most applications where captive wear bends are not likely to be subject to high temperatures and is impervious to moisture which makes it ideally suited to applications in damp and wet conditions, it can be used safely in direct contact with food, it has an extremely low coefficient of friction whilst retaining excellent wear resistant properties. In all, corrothene is the ideal material for captive wear bends in all industries.

Corromide wear bends are suitable for use at more elevated temperatures and where sharp edges such as broken glass or aggregate containing flint are likely to be encountered. Wear bends are usually manufactured from one of the self lubricated grades such as corromide COF (oil impregnated) or corromide CSL (which contains a solid lubricant)