Difference between revisions of "En-Masse Conveyors"

(Created page with "Category:Conveying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

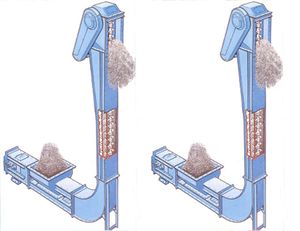

[[File:En-masse conveyors.jpg|thumb|right|En-Masse Conveyors]] | |||

[[File:En-masse conveyors1.jpg|thumb|right|En-Masse Conveyors]] | |||

'''En-Masse conveyor''' is a material handling equipment to convey the material for medium amd shorter distance by dragging the material with the help of chain link assembly. The constructional feature comprises of conveyor in three segments. They are drive end casing segment, tension end casing segment and intermediate casing segment. | |||

The drive end segment consist of drive sprocket mounted on shaft and shaft coupled with drive arangement though transmission chain arangement or coupling. Similarly tension end casing segment consist of trailing wheel mounted on shaft having a tension end acccessories of screw or spring take-up arrangement to adjust the chain tension. Intermediate casing segement shall house the chain and wear strip. [[Conveyors]] shall be mounted on structural support either fixed or sliding considering the operating temperature. At elevated temperature the design of drive end casing changes in order to compensate the thermal expansion of chain link. | |||

En-Masse Conveyors feature a highly flexible design that allows a single machine to replace several conventional units such as feeders, conveyors and bucket elevators. They can be used for both horizontal and vertical conveying of virtually any free-flowing bulk material. Capacities over 800 tons per hour are possible in a single machine, at material temperatures up to 900 degrees F. | |||

==Benefits== | |||

* Completely enclosed for clean plant operation | |||

* Large capacities for conveying in a compact space | |||

* Conveying that inclines up to 90 degrees | |||

* Variety of side and bottom abrasive resistant steel liners | |||

* Liners that are quickly replaceable without parting or removing the chain | |||

* Liner fasteners that are positioned clear of material flow | |||

* Unique tapered rail design | |||

Latest revision as of 09:21, 23 August 2012

En-Masse conveyor is a material handling equipment to convey the material for medium amd shorter distance by dragging the material with the help of chain link assembly. The constructional feature comprises of conveyor in three segments. They are drive end casing segment, tension end casing segment and intermediate casing segment.

The drive end segment consist of drive sprocket mounted on shaft and shaft coupled with drive arangement though transmission chain arangement or coupling. Similarly tension end casing segment consist of trailing wheel mounted on shaft having a tension end acccessories of screw or spring take-up arrangement to adjust the chain tension. Intermediate casing segement shall house the chain and wear strip. Conveyors shall be mounted on structural support either fixed or sliding considering the operating temperature. At elevated temperature the design of drive end casing changes in order to compensate the thermal expansion of chain link.

En-Masse Conveyors feature a highly flexible design that allows a single machine to replace several conventional units such as feeders, conveyors and bucket elevators. They can be used for both horizontal and vertical conveying of virtually any free-flowing bulk material. Capacities over 800 tons per hour are possible in a single machine, at material temperatures up to 900 degrees F.

Benefits

- Completely enclosed for clean plant operation

- Large capacities for conveying in a compact space

- Conveying that inclines up to 90 degrees

- Variety of side and bottom abrasive resistant steel liners

- Liners that are quickly replaceable without parting or removing the chain

- Liner fasteners that are positioned clear of material flow

- Unique tapered rail design