Difference between revisions of "Steam Tube Dryers"

Jump to navigation

Jump to search

(Created page with "Category:Drying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

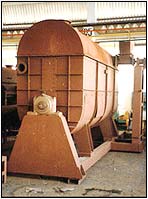

[[File:Steam_Tube_Dryers.jpg|thumb|200px|right|Steam Tube Dryers]] | |||

The '''Steam Tube Dryers''' have become so common in these days and are used widely over the chemical industry. | |||

==Operating Principle== | |||

The wet feed which has free flowing granular form is made to work over the rotating bundle of heated tubes. Due to radiation and conduction effects, the moisture is evaporated and the product becomes progressively dry as it travels across the dryer and reaches final moisture level at the discharge point. Due to effective turbulence the solids are dried uniformly. | |||

==Special Features== | |||

* Effective in handling granular, free flowing solids. | |||

* Surface as well as bound moisture can be removed. | |||

* Very uniform drying/cooling action. | |||

* High thermal efficiency | |||

* High evaporation rates | |||

* Continuous operation | |||

* Compact installation | |||

==Typical Applications== | |||

* Maize Germ | |||

* Agro Waste | |||

* Husk | |||

* Fibre | |||

* Salt Crystals | |||

* Seeds | |||

* Fish Meal | |||

* Gluten Meal | |||

* Saw Dust | |||

* Wood Chips | |||

Latest revision as of 06:00, 2 August 2012

The Steam Tube Dryers have become so common in these days and are used widely over the chemical industry.

Operating Principle

The wet feed which has free flowing granular form is made to work over the rotating bundle of heated tubes. Due to radiation and conduction effects, the moisture is evaporated and the product becomes progressively dry as it travels across the dryer and reaches final moisture level at the discharge point. Due to effective turbulence the solids are dried uniformly.

Special Features

- Effective in handling granular, free flowing solids.

- Surface as well as bound moisture can be removed.

- Very uniform drying/cooling action.

- High thermal efficiency

- High evaporation rates

- Continuous operation

- Compact installation

Typical Applications

- Maize Germ

- Agro Waste

- Husk

- Fibre

- Salt Crystals

- Seeds

- Fish Meal

- Gluten Meal

- Saw Dust

- Wood Chips