Absolute Encoders

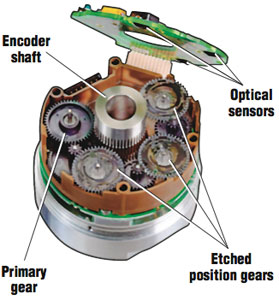

Absolute Encoder maintains position information when power is removed from the system. The position of the Encoders are available immediately on applying power. The relationship between the encoder value and the physical position of the controlled machinery is set at assembly; the system does not need to return to a calibration point to maintain position accuracy. Incremental Encoders accurately record changes in position, but does not power up with a fixed relation between encoder state and physical position. Devices controlled by incremental encoders may have to go home to a fixed reference point to initialize the position measurement. A multi-turn absolute rotary encoder includes additional code wheels and gears. A high-resolution wheel measures the fractional rotation, and lower-resolution geared code wheels record the number of whole revolutions of the shaft.

An absolute encoder has multiple code rings with various binary weightings which provide a data word representing the absolute position of the encoder within one revolution. This type of encoder is often referred to as a parallel absolute encoder.

How absolute encoder work

Using this measuring system, every position of the measurement range or angle is identified by a definite code on a glass or plastic disc. This code is represented on the disc in the form of light and dark regions within different tracks. This combination relates to an absolute numerical value. Thus, the position value is always directly available, counters are not necessary. In addition it is not possible to get continuously invalid values caused by interferences or loss of the supply voltage. Movements which are done while the system is turned off are immediately measured after the system is powered up.

Encoder technologies

Encoders may be implemented using a variety of technologies:

- Conductive tracks. A series of copper pads etched onto a PCB is used to encode the information. Contact brushes sense the conductive areas. This form of encoder is now rarely seen except in digital multimeters.

- Optical. This uses a light shining onto a photodiode through slits in a metal or glass disc. Reflective versions also exist. This is one of the most common technologies.

- Magnetic. Strips of magnetised material are placed on the rotating disc and are sensed by a Hall-effect sensor or magnetoresistive sensor. Hall effect sensors are also used to sense gear teeth directly, without the need for a separate encoder disc.