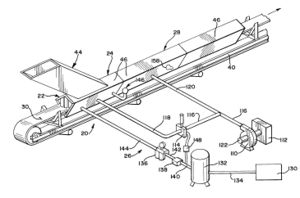

Air Supported Conveyors

Air Supported Conveyors uses low-pressure air to support the loaded belt in place of traditional troughing rollers. This revolutionary concept minimizes friction, lowers power consumption, requires minimum maintenance, and is remarkably quiet and environmentally friendly. A multipressure plenum system for supporting a conveyor belt of a gas supported belt conveyor and method of operation. The multipressure plenum system includes a multipressure plenum having a support surface including a plurality of apertures and a chamber in fluid communication with the apertures. The chamber of the plenum is in selective fluid communication with a first source of gas at a first pressure, and is in selective fluid communication with a second source of gas at a second pressure. Gas from the first source of gas at the first pressure flows through the apertures in the plenum to form a gas cushion which supports the conveyor belt above the plenum. Gas from the second source of gas at the second pressure selectively flows through the apertures in the plenum to provide additional support to the conveyor belt.

Features and Benefits

- The totally enclosed conveyor system acts as its own ductwork to prevent the escape of airborne dust

- Stabile belt path reduces spillage; enclosed system controls dust emission.

- Low friction material transportation system means less wear on belt; true tracking system prevents edge damage.

- Low friction system can reduce conveyor power consumption by 30%. You pay less for energy, and your conveyor may need a smaller drive.